I think this project is quite a bit more complex than you may be expecting. There are a lot of parts that need changing, and as @microMerlin points out, pretty much all will need to be obsoleted as the size of the schematic svg is going to change if we choose to use my new svg, set to the same size as a resistor (which I am in favor of!) In this list I extracted everything I could identify as a pot in core parts, then started looking at the .fzp and .svg files to see what needs work. If we are making changes I am in favor of upgrading all the parts to the graphics standards and the parts file format. As well any svgs currently dimensioned in px (which causes scaling problems) need to be rescaled and set to in or mm (which avoids the scaling problems. As well I would like to see the scale of the svgs all changed (if needed) to 10.41667 (1 drawing unit = 1 thou inch as recommended in the part file format document.) As well the colors (mostly in schematic and pcb) need to be updated to match the graphics standards, many of the older parts do not comply. Here is my list of the parts I think need to change with the non Sparkfun ones with a list of what I immediately see needs to change about them. These are listed by the name of the .fzp file in fritzing-parts\core followed by each of the svgs and what I see wrong with it. In addition we should review the family and selector settings on all parts to make sure they are correct. I believe that all parts in a family need to have the same number of pins with identical function so the swapping mechanism can swap parts (for instance between a tht version and an SMD version) but I’m not sure this is correct. Each family member needs to have a unique selector field of some kind as well. I would like to see consistency in the properties field as well (basically a core set of fields like family, variant, layer etc, which should be in all parts ideally.) We may need to step back one step and discuss (and change the parts file format docs!) the desired format of new parts to get consistency as the first step.

Here is the (possibly incomplete!) list of pots I found in core

(I think the fabric pots may be missing in this list for instance!):

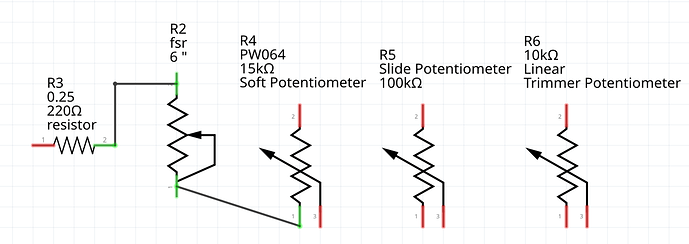

basic_fsr.fzp

family FSR

add variant, and layer properties

breadboard basic_fsr.svg

dim in scale 1.04167

wrong scale, unneeded terminalIds, incorrect grouping (connectors outside of breadboard group!)

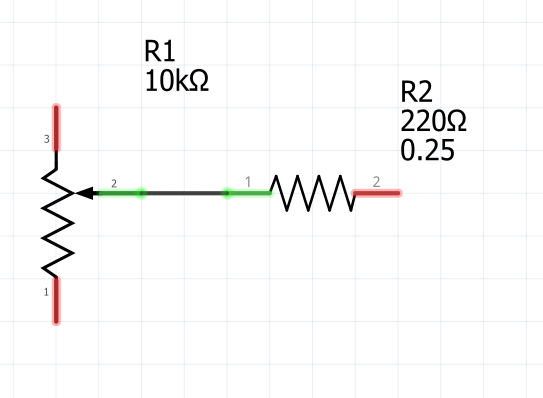

schematic basic_fsr.svg

dim px scale 1.00000

wrong dim (rescale will fix), wrong scale, wrong symbol (needs to change to the one in the post!) wrong colors for lines (#787878 instead of #555555)

pcb jumper_2_100mil_pcb.svg

no svg by this name in core parts! Add a real svg file so it isn't substituted from an unknown svg!

Dial Potentiometer with switch.fzp

family Potentiometer

"type">Thumb Wheel Potentiometer with switch<

add variant, layer properties

breadboard potentiometer_w_switch.svg

dim in scale 0.75000

the rest of the svgs are Dial_Potentiometer_with_switch rename to be consistent? Need to check for other parts using potentiometer_w_switch.svg though. Wrong scale, has unneeded terminalIds in breadboard. Connectors outside breadboard group.

doesn't appear to be used other than here:

$ grep -R potentiometer_w_switch.svg ./

Binary file ./.git/index matches

./core/Dial Potentiometer with switch.fzp:

so the rename should be done to make the fzp more consistent.

schematic Dial_Potentiometer_with_switch_pcb.svg

dim px scale 1.0000

replace with new schematic svg will fix the problems.

pcb Dial_Potentiometer_with_switch_pcb.svg

dim in scale 0.75000

wrong scale, silkscreen color is white instead of black

pot_big.fzp

family Potentiometer

type">Rotary Shaft Potentiometer<

breadboard potentiometer.svg

dim in scale 0.75104

wrong scale

schematic basic_poti.svg

dim px scale 1.0000

dim wrong scale wrong, replace with new svg will fix both problems.

pcb jumper_3_200mil_pcb.svg

should be replaced with a silkscreen that shows the outline of the pot ...

pot_trimmer_6mm.fzp

family Potentiometer

type">Trimmer Potentiometer<

breadboard potentiometer_trimmer.svg

dim in scale 1.04167

needs re scale. has terminalIds which it doesn't need. Could change the terminals to pin and remove the breadboard terminalId in the fzp file.

schematic basic_poti.svg

dim px scale 1.0000

dim wrong scale wrong, replace with new svg will fix both problems.

pcb trimpot_meggitt_pih

dim in scale 10.41667

silkscreen color is white and needs to change to black. Silkscreen appears much too small! only 2mm which seems unlikely to be accurate.

pot_trimmer_12mm.fzp

family potentiometer

type">Trimmer Potentiometer

Size">Trimmer - 12mm<

breadboard potentiometer_trimmer.svg

set for bendable legs but the svg is not, may not work correctly and needs to be corrected! Otherwise same issues as 6mm trimmer (same svg)

schematic basic_poti.svg

same as 6mm version above

pcb trimpot.svg

correct scale, silkscreen color is white, needs to change to black.

pot-slider.fzp

family Potentiometer

type type">Slide Potentiometer<

breadboard pot-slider.svg

dim in scale 0.75000

needs a rescale, has unneeded terminalIds, could be simplified to just the pin.

schematic basic_poti.svg

dim px scale 1.0000

dim wrong scale wrong, replace with new svg will fix both problems.

pcb pot-slider.svg

dim in scale 10.41667

silkscreen color is white, needs to change to black.

these I have identified as pots but not examined in detail yet:

sparkfun-electromechanical-pot-.fzp

sparkfun-electromechanical-pot_switch-pot_pth.fzp

sparkfun-electromechanical-pot_switch-pot_pth_switch.fzp

sparkfun-electromechanical-pot-100k_3362u.fzp

sparkfun-electromechanical-pot-mam.fzp

sparkfun-electromechanical-pot–rv16af-20.fzp

sparkfun-electromechanical-pot-trim.fzp

sparkfun-electromechanical-trimpot–2.fzp

sparkfun-electromechanical-trimpot-3mm-2.fzp

sparkfun-electromechanical-trimpot-3362u-2.fzp

sparkfun-electromechanical-trimpot-pth.fzp

sparkfun-electromechanical-trimpot-smd.fzp

sparkfun-electromechanical-trimpot–pth-knob.fzp

sparkfun-electromechanical-trimpot-smd.fzp

sparkfun-electromechanical-trimpot-trimpot_pth_s3_lock.fzp

sparkfun-electromechanical-trimpot-trimpot-5mm.fzp

Peter

)

)