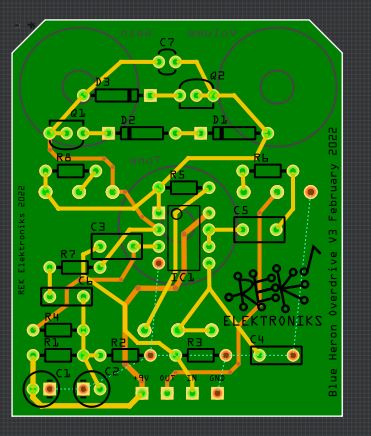

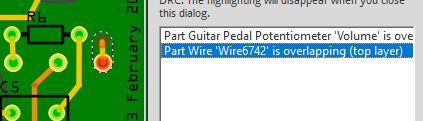

This was a fairly easy one. There is an error in your custom pot part which is causing the DRC error (there are actually a number of problems in the part.) Correcting the error fixes DRC (thankfully!)

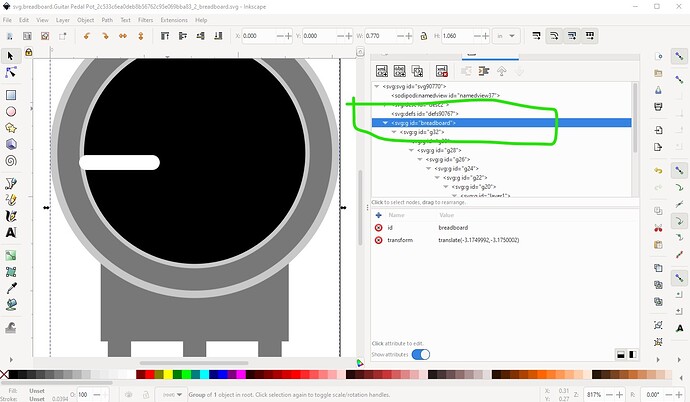

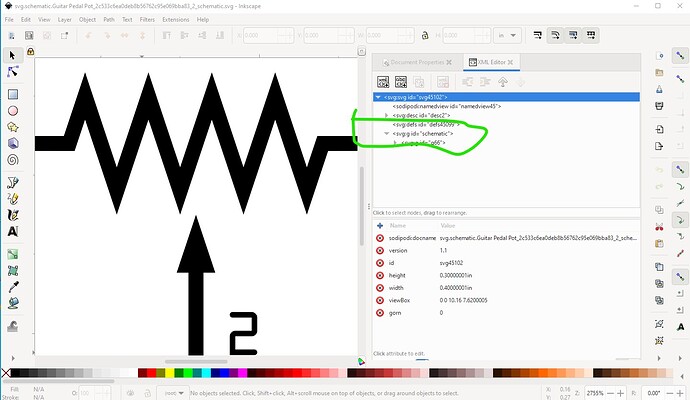

First layerIds are missing in breadboard and schematic. The only problem I know this causes is the part won’t export as an image. It is easy to fix just add an appropriate layerId to the top group like this:

same in schematic

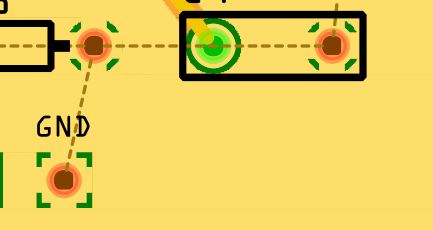

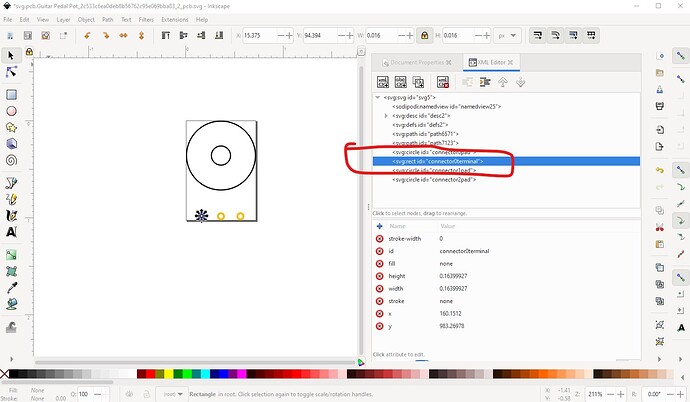

the problem here is in the pcb svg though, there is a terminalId on the pad causing the DRC error

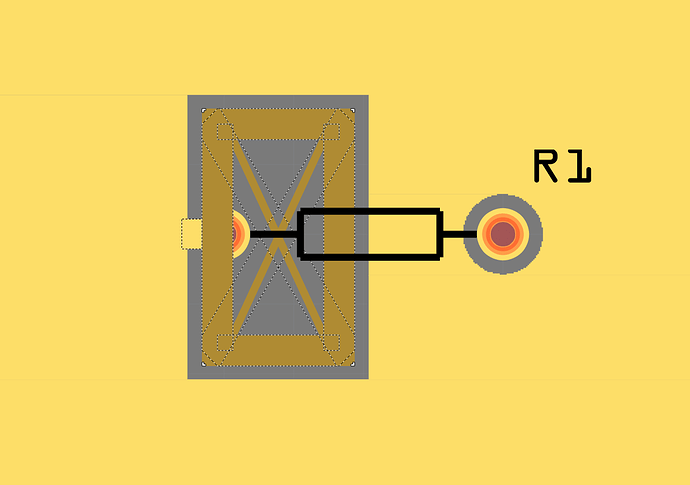

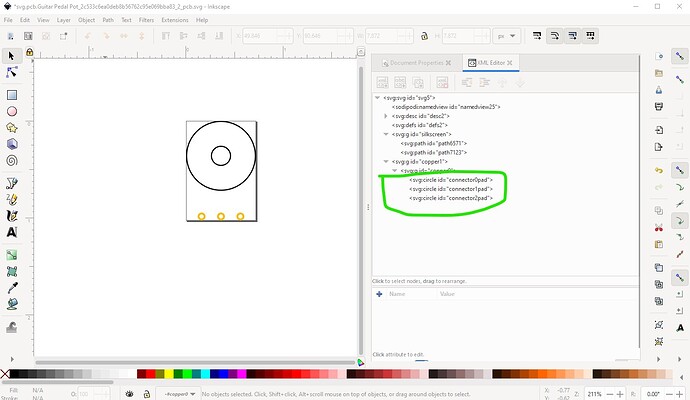

removing this from the svg and the .fzp file fixes the issue.

I also simplified and rescaled the svg but removing the terminalId is the important part. Then I updated the .fzp file to remove the terminalId from there. In the .fzp file

<connector type="male" name="1" id="connector0">

<description>Input-GND</description>

<views>

<breadboardView>

<p layer="breadboard" svgId="connector0pin"/>

</breadboardView>

<schematicView>

<p layer="schematic" svgId="connector1pin" terminalId="connector1terminal"/>

</schematicView>

<pcbView>

<p layer="copper0" svgId="connector0pad" terminalId="connector0terminal"/>

<p layer="copper1" svgId="connector0pad"/>

</pcbView>

</views>

</connector>

needs to become

<connector type="male" name="1" id="connector0">

<description>Input-GND</description>

<views>

<breadboardView>

<p layer="breadboard" svgId="connector0pin"/>

</breadboardView>

<schematicView>

<p layer="schematic" svgId="connector1pin" terminalId="connector1terminal"/>

</schematicView>

<pcbView>

<p layer="copper0" svgId="connector0pad"/>

<p layer="copper1" svgId="connector0pad"/>

</pcbView>

</views>

</connector>

I then changed the moduleId variant and file names to make this a new part. I see that the pin numbering in schematic is odd, but I didn’t correct it. It is preferable to have all the connector numbers match the id field (connector1 in this case) so the connector2s are incorrect but will work (because the schematic svg is changed in the same way!)

<connector type="male" name="2" id="connector1">

<description>Output</description>

<views>

<breadboardView>

<p layer="breadboard" svgId="connector1pin"/>

</breadboardView>

<schematicView>

<p layer="schematic" svgId="connector2pin" terminalId="connector2terminal"/>

</schematicView>

<pcbView>

<p layer="copper0" svgId="connector1pad"/>

<p layer="copper1" svgId="connector1pad"/>

</pcbView>

</views>

</connector>

All these changes are in this part

Guitar Pedal Potentiometer-fixed.fzpz (6.6 KB)

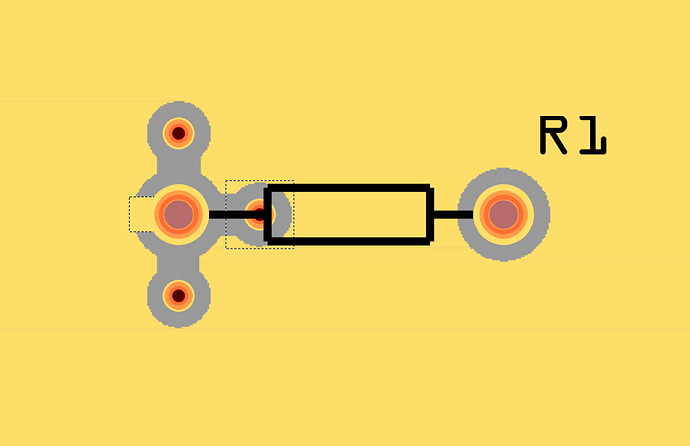

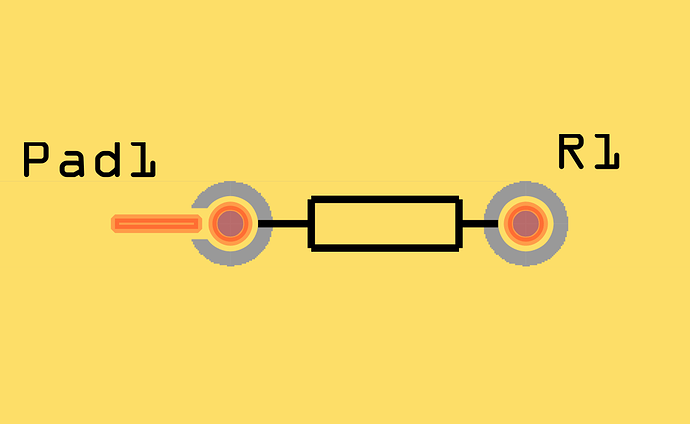

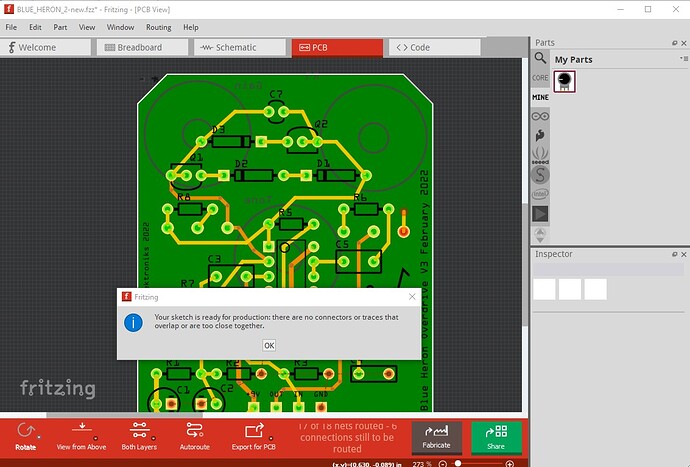

which I then substituted in to your .fzz file by doing a delete minus on the pot giving the error and replaced it with my new part. The delete minus removes the part but leaves the connections, you then need to grab the end of the connection and move it to reconnect the trace to the new part. With that done now DRC passes.

in this .fzz file (note I didn’t remake the connections in breadboard or schematic only pcb!)

BLUE_HERON_2-new.fzz (120.2 KB)

Peter