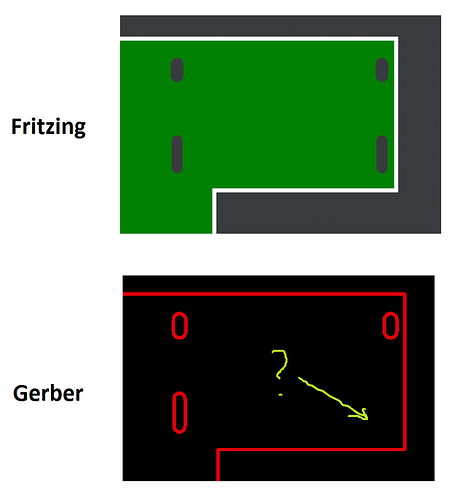

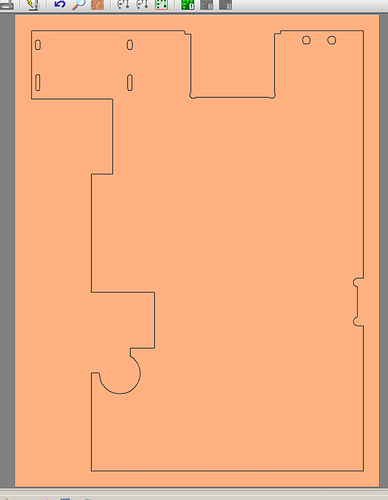

Because I make my PCB’s via CNC milling, which always points out the problems with cutouts, I spent many hours trying to figure out work-arounds.

Thus, that is why I stated my comments in above posts - e.g., size, proximity, etc, etc, etc… and that “you can get there with a bit of work”

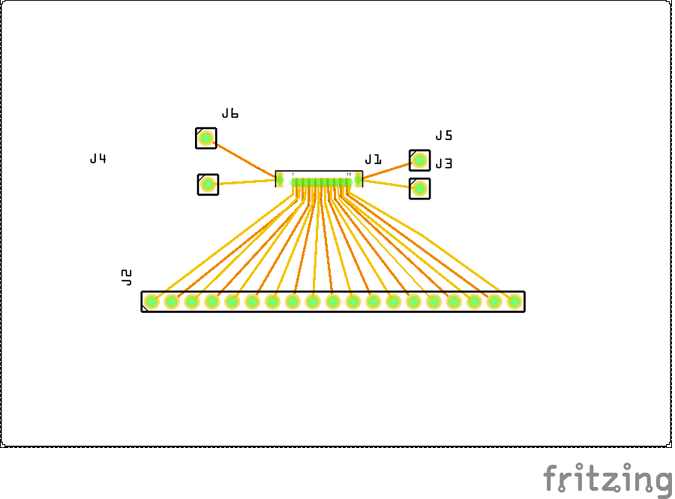

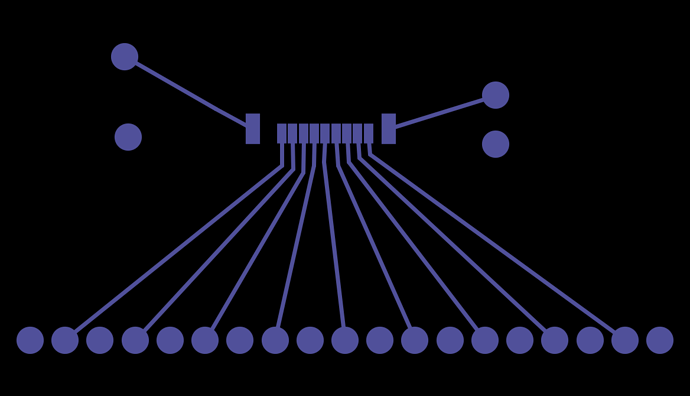

To help (Peter’s) investigation, the following two additional files are attached along with images of svg data:

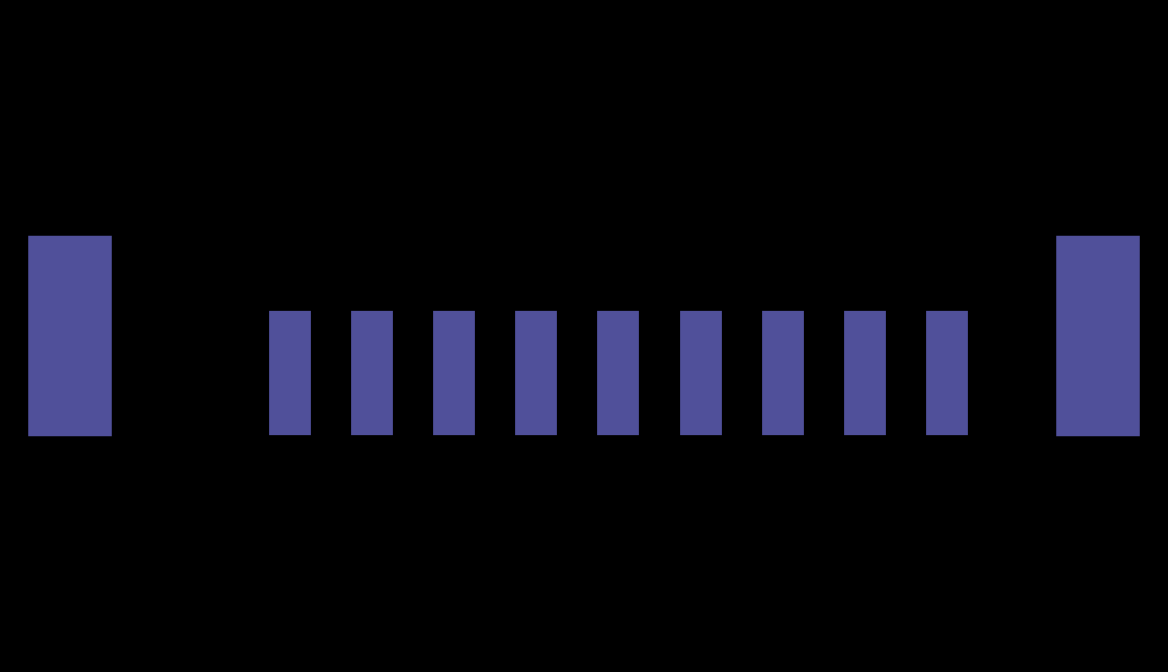

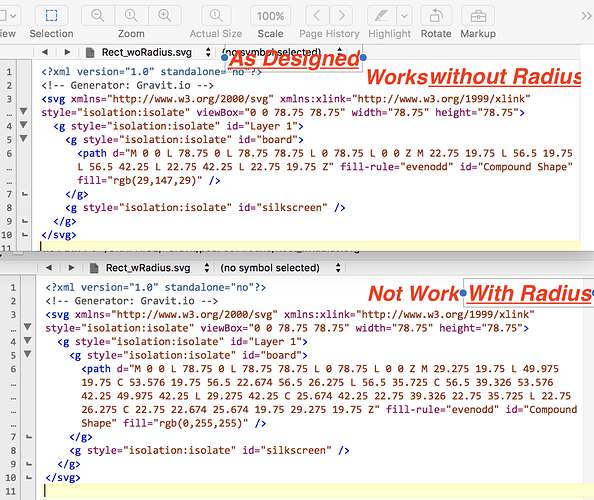

These two attached files are minimal, containing:

Empty Silkscreen layer

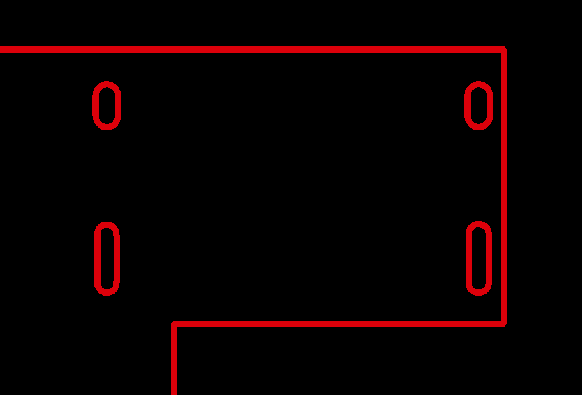

Board layer with Rectangles (for board and cutout), and Differenced the two rectangles (thus resulting in a Path)

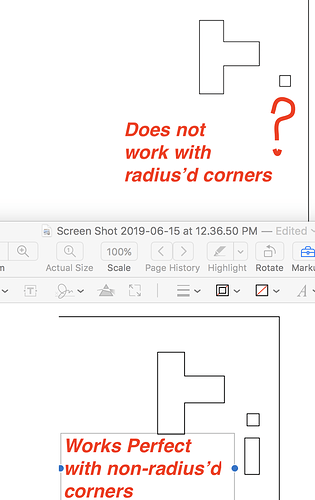

One file has 90º corners

One file has Radius’d corners

Both drawn in Pixel units (78.8px)

Thus, only difference in ‘Designed’ SVG’s are the data points regarding the corners. Units are undefined, thus assumed to be px.

I’m thinking, regardless of Units, whether specifically defined (px, mm, inch) or not, the only logical resulting difference should be the size, if units is the issue.

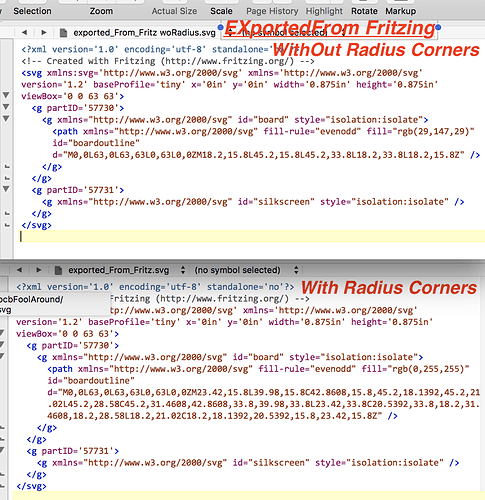

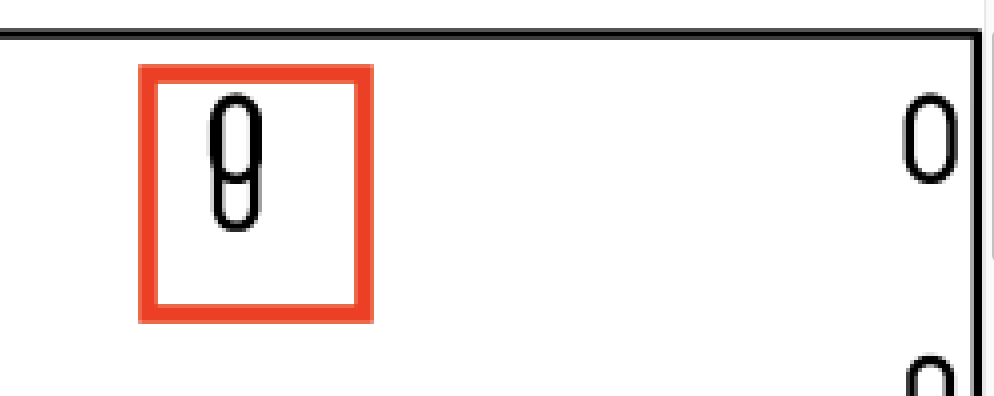

Fritzing loads both files with result of 22.2mm

After loading, I exported both of them from Fritzing as SVG images. The results show both with the same Correct Inch dim’s. Other differences appear to be non-consequential.

Rect_wRadius.svg.fzp (733 Bytes)

Rect_woRadius.svg.fzp (566 Bytes)