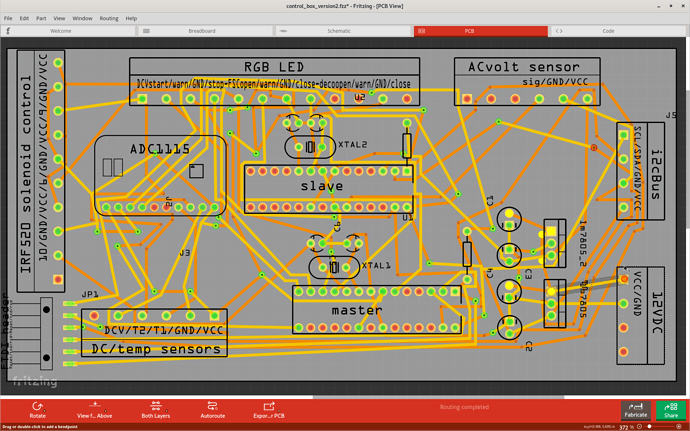

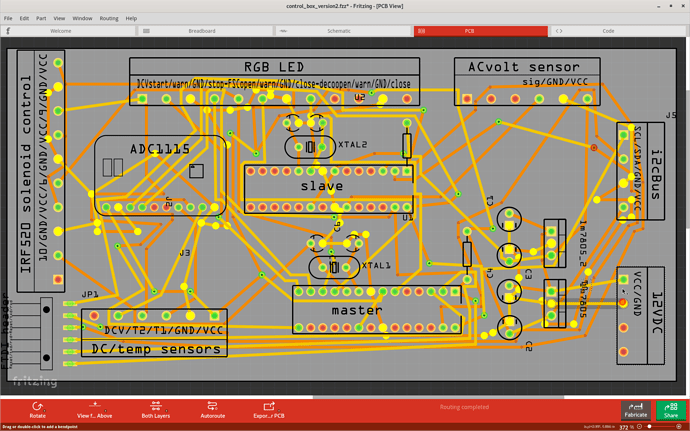

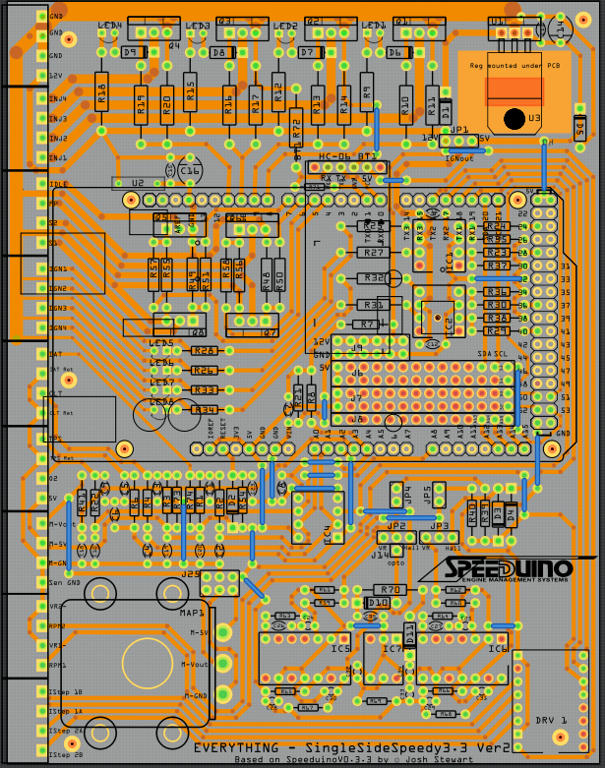

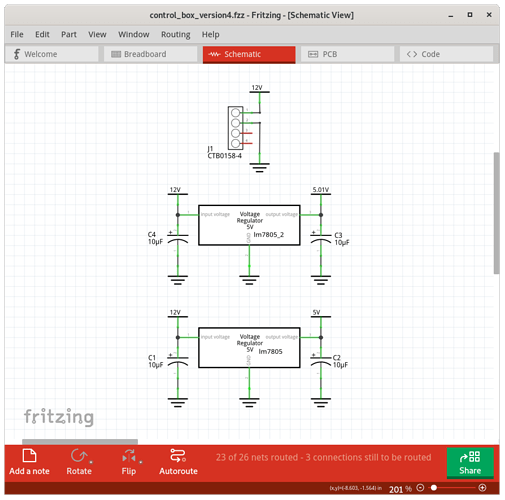

Right duh. “%” is shifted “5” on most keyboards. A simple typo. My comments and images still apply. There is no link shown between the 12V net and the regulator 5V output net connections, and the 5V lines from both regulators seem to be going to reasonable places.

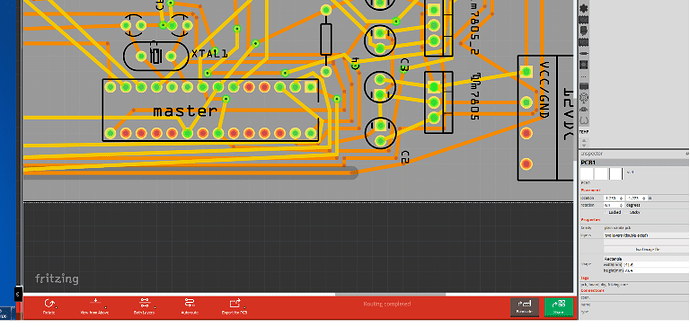

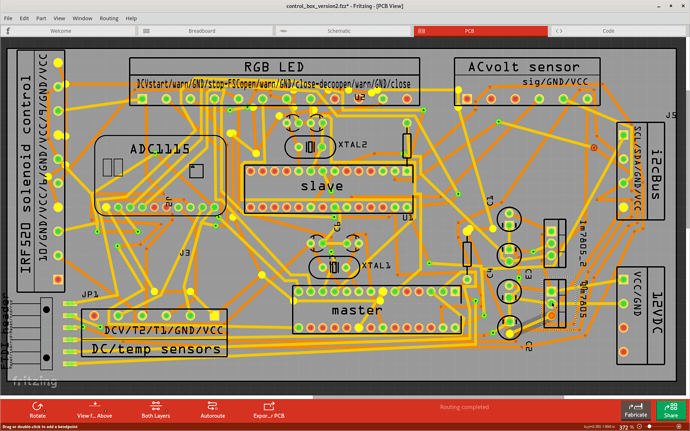

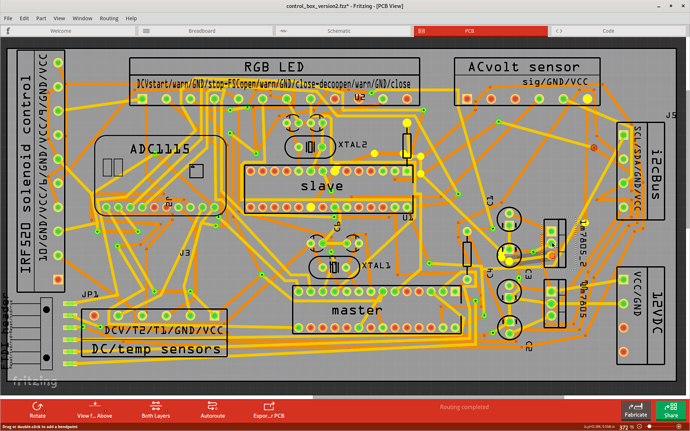

I wouldn’t say “never”, but when using it, be prepared to do a lot of manual cleanup of the result. It won’t take much practice to get cleaner routing manually than what auto-routing generates. Cleanup up the mess that auto-routing makes can be the start of that practice.

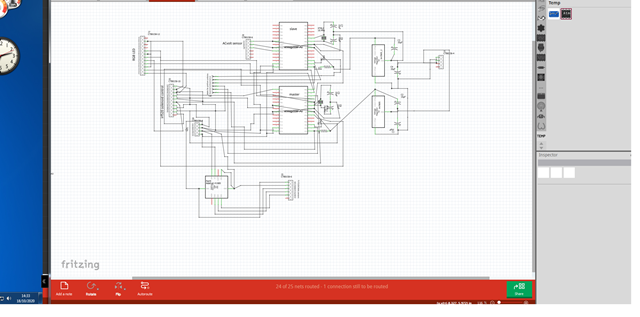

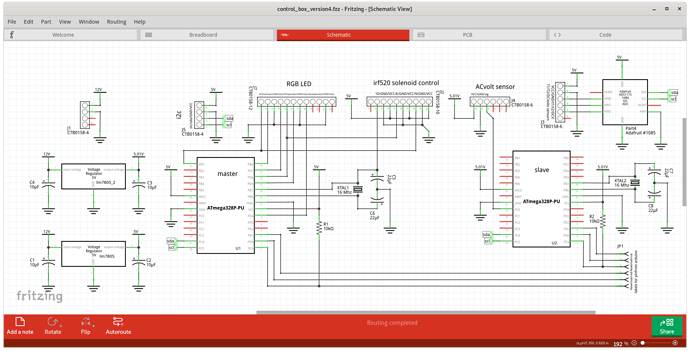

The schematic view is (also) rather messy, and a lot more difficult to follow than it needs to be. From the brief description, you have been editing and making changes quite a lot to get here. You should (fairly regularly) cleanup to simplify the layout and routing. None of this is analysis how your circuit works. Just how it is presented on the schematic.

One thing that can quickly reduce the clutter, is replacing all of the ground wires with the standard GND symbol. Instead of running actual wires between components, just place GND symbols at convenient points, and connect to them. All of the GND symbol are connected together by invisible wires. The same works for power connections. There is a standard Power (V++) symbol that can replace the majority of the power rail wires. Your circuit makes that one a bit tricky, because you have 2 separate voltage regulators outputting the same voltage, but not on the same rail. That can be ‘fudged’ (in Fritzing) by setting one set of the power symbols to a slightly different voltage. All of the ‘Power’ symbols set to (exactly) the same voltage are connected by invisible wires. With that, one way to layout the power input and regulation section of the schematic would be.

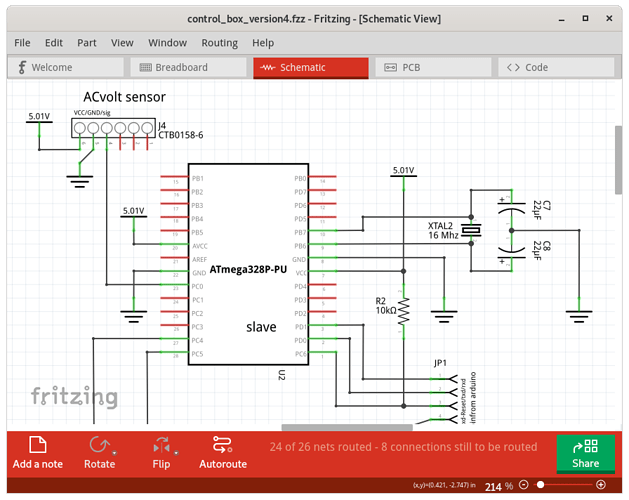

Incorporating that, and moving parts around, here is what the circuit around the slave microcontroller could look like.

Power and GND are not the only possible symbols that can be used to electrically connect distant pins. There is a generic “Net label” part. A pair (or more) of those with the same label are connected by invisible wires. Very useful for tying pins to a common bus, like I2C. Adding net labels named “sda” and “scl” for each connection to I2C simplifies the schematic wiring diagram. When using the net labels (or power symbols), it can be easiest to place one generic part, change the label, then duplicated it as many times as needed. Instead of placing the generic part, and changing the label, each time. After some more adjusting, to group parts, and reduce visual interference between wires, I ended up with this.

This is not ‘perfect’ (or professional), but it is (to me) a lot easier to understand how the pieces interact. One of the things to improve, is the labeling. A single string with the names for all of the pins on a connector is simpler, but does not stay lined up very well. With a couple hints from some of the text, the labels are referencing Arduino (UNO) pins, but the schematic is using the raw microcontroler parts. I assume because the circuit was breadboarded using Arduino boards, not the chips, and that was an aid to keep the wiring straight.

As @Old_Grey said about the PCB, there are tutorials around that can help fill in the concepts, guidelines, processes to use to get more readable layouts.

Some people do sudoko, crossword, jigzaw puzzles. I play with layouts.

Similar cleanup could be done with the breadboard view. Breadboard view would also benefit from using the breadboard part to place the raw components on. It is not used (or needed) as often on schematic view, but on breadboard view, setting the color for individual wires can make tracing the circuit easier. Black for ground, Red for power rails, a colour for sda, different for scl. More colours, with and without banding, for other data lines.