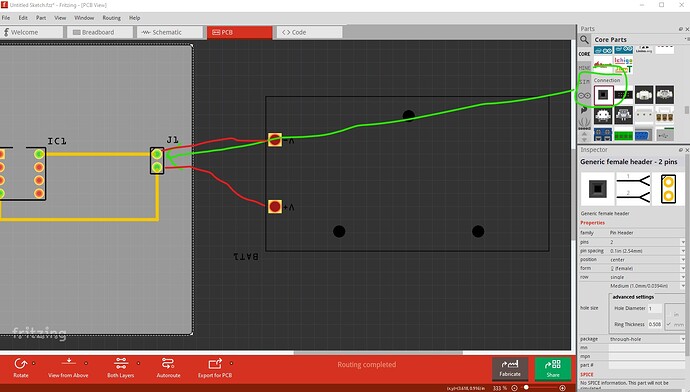

No. The pads need to be inside the grey pcb area. Everything outside that area will be truncated and not appear on the board. To put pads on the board the easiest way is likely to put a 2 pin header (which will produce a pad to solder a wire to) on the edge of the board like this:

the red line are wires from the board to the power supply.

The same thing applies here, if you change the number of pins from 2 to 5 you will get a 5 pin connector. The rub is that unless you change the motor part you will have to manually route the motor connections to the new connector. A better bet would likely to be to use the 5 pin stepper motor (found by a google search of the form “fritzing part 5 wire stepper motor” which in general is a good way to find parts.

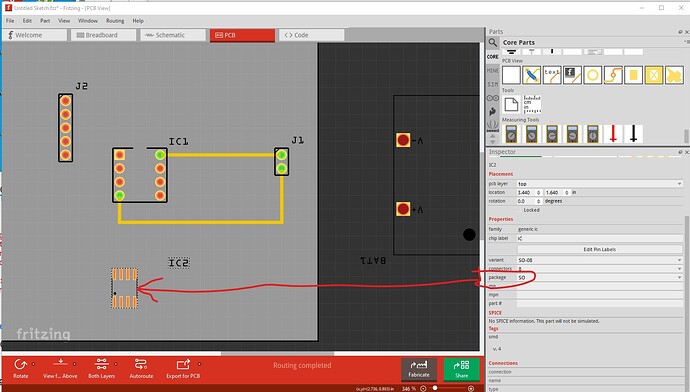

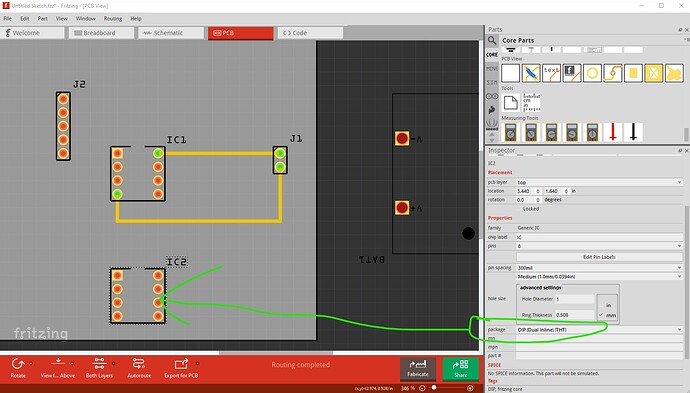

The IC you have selected (modifiable in Inspector like the header) is SMD so it has no holes as it solders to the top of the board. If you wanted holes you need to select a THT part like this:

your current part

that you likely want

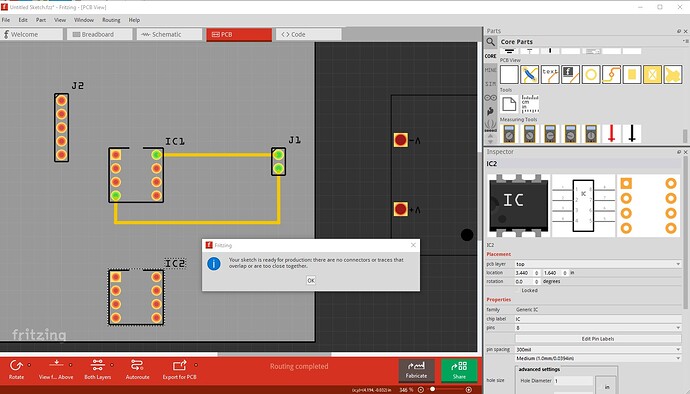

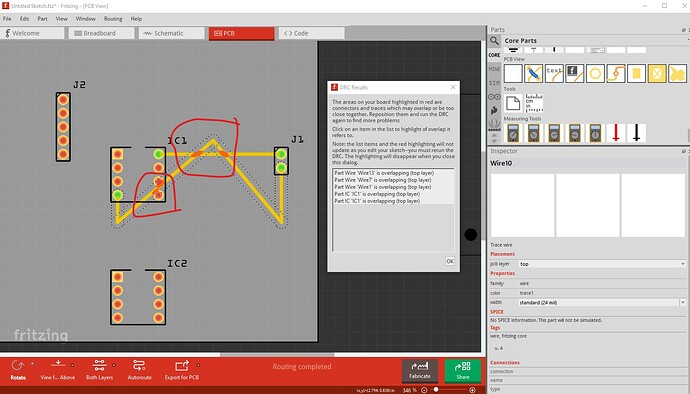

In general autorouting is convenient but almost always a poor choice. As well you need to run DRC (which will almost certainly fail on your board) like this:

This is the desired outcome DRC passes

your board is likely to look like this

where it has flagged the various errors with red marks. To correct you layout you manually need to click on the traces and move them to the appropriate place. It can help to set the grid size smaller via View->set grid size as well although for a simple board the standard 0.1in grid is fine.

Hope this helps and feel free to ask further if it doesn’t.

Peter