The viewBox value looks ‘odd’ for something using drawing dimensions of 60 by 70 mm. A little math says that was probably created using 720 px per inch, then converted to mm. Or actually, the 60 by 70 mm was converted to inches, then the drawing done at 720 px per inch, and results switched back to mm.

That works. I normally do new graphics using either 1000 px per inch (1 px = 1mil), when working in inches, or 100 px per mm when working in mm. That makes most of the coordinate numbers simpler for the general cases.

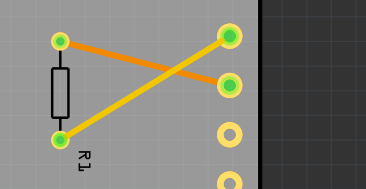

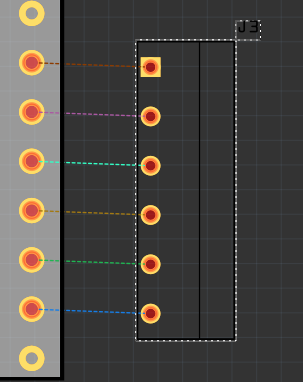

Since it contains silkscreen, copper0, copper1, that appears intended to be the graphic to use in a part definition. A bit unusual, in that the top and bottom connector circles are duplicated, AND the copper1 is inside copper0. Extracted and truncated, that should be something like either:

<g id="copper0">

<circle cx="651.96" cy="130.39" fill="none" id="pin1.1" r="15.59" stroke="#f9a435" stroke-width="7.08"/>

<circle cx="723.96" cy="130.39" fill="none" id="pin1.1" r="15.59" stroke="#f9a435" stroke-width="7.08"/>

</g>

<g id="copper1">

<circle cx="651.96" cy="130.39" fill="none" id="pin1.1" r="15.59" stroke="#f9a435" stroke-width="7.08"/>

<circle cx="723.96" cy="130.39" fill="none" id="pin1.1" r="15.59" stroke="#f9a435" stroke-width="7.08"/>

</g>

for distinct elements (not good for tht), or

<g id="copper1">

<g id="copper0">

<circle cx="651.96" cy="130.39" fill="none" id="pin1.1" r="15.59" stroke="#f9a435" stroke-width="7.08"/>

<circle cx="723.96" cy="130.39" fill="none" id="pin1.1" r="15.59" stroke="#f9a435" stroke-width="7.08"/>

</g>

</g>

for a single element that exists on both sides (standard tht)

For this to be used in a part, the circles in the copper groups would need connector«number»pin ids matching the part definition. To get some graphics to work with, this is fine, though technically, the id values should be unique.

All of the graphics for silkscreen should be black. fill and/or stroke as needed for the element. The stroke for the boundary rectangle is not large enough to be seen. The start and dimensions also need adjusting to be fully within the part. Half of the stroke is drawn inside, half outside of the specified edges, so starting from 0, 0 means half the stroke is missing.

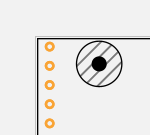

Was your intent to have holes drilled (by the board producer) for the silkscreen circles? Given the earlier conversation, I thought that the intent was to not define holes for the part, but define them for the board instead. Also, the general (not fixed) recommendation for most parts, is to create them without mounting holes. That way they can be used in cases where the mounting holes (or only some of them) are not wanted in a project. The holes can always be added to the project, by using the ‘hole’ part. Just need to mark the silkscreen (typically a “+”) so that the hole can be added accurately. If they are in the part, they can not be removed from the project.

I see nothing here to base the board image on, which is what the part would need to align to. Or, since (most) parts are easy to align to the grid, it is the board image which needs aligning. What we need for a sample case is 2 images. One for the board, the other for the part. With a know common point that they need to align too.