There is very little written guidance but we are happy to answer questions here. To that end I modified the RT424F05 part that I posted here earlier to create a part for this relay and kept notes as I went along. You could start with the RT424F05.fzpz part and try and follow the notes and see if you can create the same G2R-2.fzpz I got (and ask if you have problems). Note you can do the none svg editing part of this with Parts editor but it doesn’t tend to work well for me so I edit the underlying files instead.

edit the RT424F05 part in parts editor to change the metadata.

use 7zip to unzip G2R-2.fzpz

Breadboard svg:

In Inkscape

ungrouped everything

remove the 9th pin on the end of the chip, change the chip label (although that will happen automatically)

Renumbered the pins in to standard IC order (the top row was backward) for neatness.

edit select all

resize page to drawing or selection

group (still with select all) and change the id to breadboard.

save as plain svg

Done.

pcb:

In Inkscape

ungroup everything

Renumber the pins to match breadboard

select only the copper pads and group twice (so one group is below the other)

The new group should only have square (for pin 1) and connector0-7pin in it.

set the first group id to copper1

set the group id under copper1 to copper0

select line 7 (the top line in the silk screen in xml editor) and group it

change the resulting group id to silkscreen

now for the other 4 lines select them in xml editor and click Indent node (at the top of the xml editor box)

to add them to group silkscreen one at a time. There is no easy way to make a selection that will do this as far as I know (I’d be happy to be shown to be wrong though!)

Don’t resize the page to drawing in this case because that will add a transform to the coppers and break things.

save as plain svg and done.

Schemtic:

In Inkscape:

ungroup everything (this is painful because there are transforms and the text font sizes are now wrong and need correcting)

It is also scaled wrong so correct that first.

edit select all

resize page to drawing

record the coords in px from the tool bar

x 0 y 0 w 97.016px h 46.879px

edit->preferences->Behaviour->Transforms->Scale Stroke Width needs to be ticked (I usually want it unticked to not screw with

stroke widths when changing the size of lines in a drawing)

in document properties change scale from .75 to 10.41667 (why not 10 I don’t know, but this scales properly to 1px = 1thou in maybe because of 96px per inch?)

then click the drawing to make it take effect.

The image shrinks to the top left corner

now edit->select all

and change the tool bar coords back to those we recorded originally

and we get the original drawing again except now correctly scaled.

Font sizes are still wrong as are pin numbers and content (dual coils for instance) so now we correct that

First though untick edit->preferences->Behaviour->Transforms->Scale Stroke Width

As we no longer want it screwing with stroke widths when we change sizes of lines.

First pick a better font size in xml editor by trial and error

35 (the same as 3.5 in the parts format doc) is good. There are also scale transforms in the xml that I dislike

so using a text editor (I used vi in this case) we are going to remove the transforms and reset the font sizes.

in Inkscape file->save as-> plain svg

Switch to the directory with the fzp and svg files (I use cygwin) and run the parts check script to clean up the xml

FritzingCheckPart.py part.G2R-2_relay_300mil_38dc04ef3cdb3d12cc6cb7daec0e05b3_1.fzp

vi svg.schematic.G2R-2_relay_300mil_38dc04ef3cdb3d12cc6cb7daec0e05b3_1_schematic.svg

then delete all the translate commands.

then globally substitute the current wrong font size to 35

s/font-size=“166.3019104”/font-size=“35”/

s/fill=“#000000”/fill=“#787878”

to set a more appropriate fill color for the text

Then back to Inkscape to proceed.

Move the parts and pins around to match this relay, cleaning up previous errors (wrong fill values and stroke widths) as I go.

At the end of it all before doing the group

edit select all

resize page to drawing

edit select all

group

change the id of the created group to schematic

file->save as plain svg and save (replace)

done.

Now edit the fzp file with vi to make the changes we have in the svgs.

Change the pin descriptions to match the new relay correct a few typos and delete connector 8 which is no longer used

save it as we are done.

run

FritzingCheckPart.py part.G2R-2_relay_300mil_38dc04ef3cdb3d12cc6cb7daec0e05b3_1.fzp

correct the typos it found until we get a clean run (note it also removes the px from font-size and inlines the style xml to

keep Fritzing happy)

Use 7zip to rezip it to an fzpz file, load it in to Fritzing and test it.

Note the connectors in schematic are offset two rows to verify the terminalIds are set correctly to make the wire join the end of the pin. I

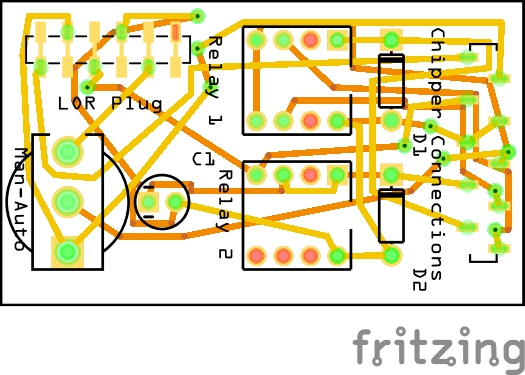

also exported the sketch as a gerber file (File->export->for production->extended gerber) and checked the hole size (.038 suitable for .1 headers) layout and silkscreen look OK outside of Fritzing.

g2r-2_test.fzz (15.5 KB)

Post it.

(this is actually already in the temp bin in the sketch above but here it is as a part):

G2R-2.fzpz (9.0 KB)

Peter