FYI…

Though I no longer use Fritzing (preferring Kicad for past few years) this may help:

First - know that various programs that can create shape files for use in Fritzing, usually have Preference panels for setting Export type and things like limiting arc behavior and arc-to-line conversions… (example; FreeCad)

That said:

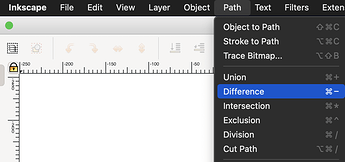

Regardless of posted info and documentation indicating Fritzing needs Layers defined in the file, they really don’t. You can create a PCB svg file by just drawing the shape and saving/exporting the SVG. I’ve done that with a handful of drawing programs.

I just now did this to confirm my poor Fritzing-user memory.

In fact, here’s what I just did to confirm Happiness!

Created a PCB Shape in FreeCad (no layers, did nothing beyond draw it) and Extruded it to fill-in the shape as a solid.

Exported it as Flattened SVG.

The SVG file size is 3kb (very small)

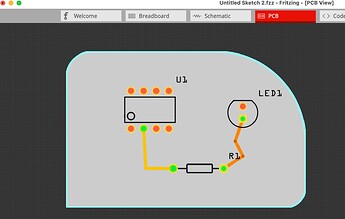

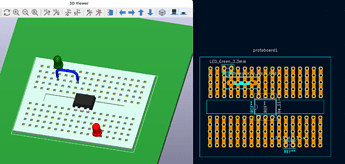

In Fritzing (my old version) I loaded the PCB shape and added a couple of Parts to it and added Tracks to Top & Btm

Then, Exported Gerber’s for Production.

Also, Exported to PDF

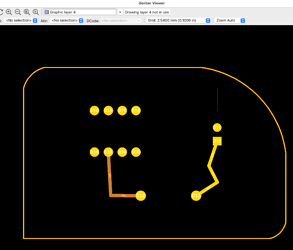

Then, with GerbView (Kicad’s Gerber viewer), I opened the Gerbers. No problem.

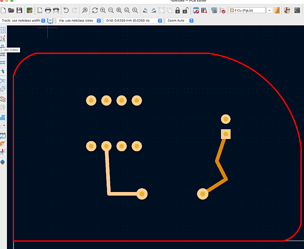

Then, I exported-to-PCB (a feature in GerbView)

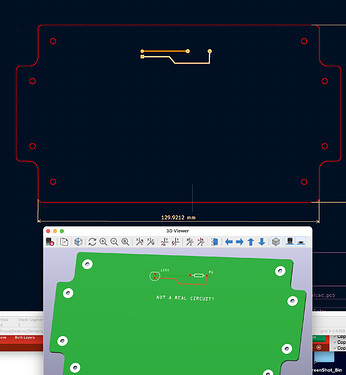

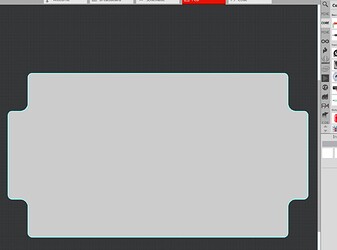

Then, I opened the exported PCB and moved the PCB’s shape to the Edge-Cuts layer (that’s where Kicad wants the shape). No problem

Some screenshots… Mostly to show/confirmation…

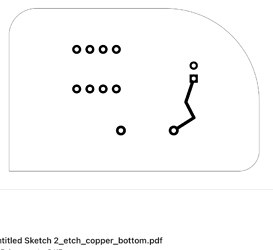

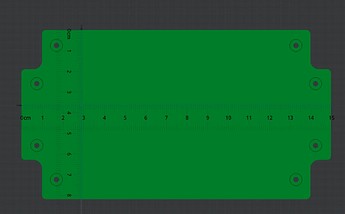

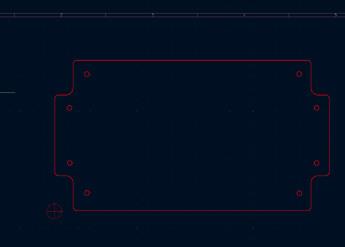

PCB Loaded Into Fritzing

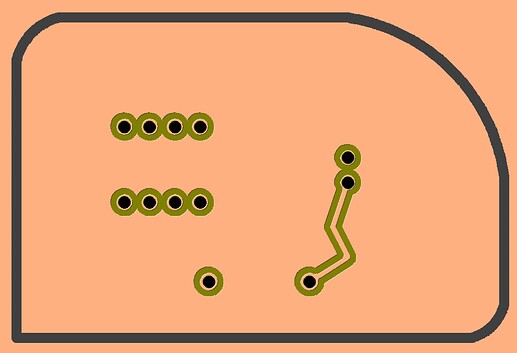

In GerbView

In Kicad, Moved Shape To Edge_Cut Layer

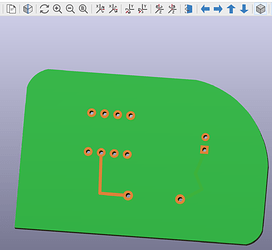

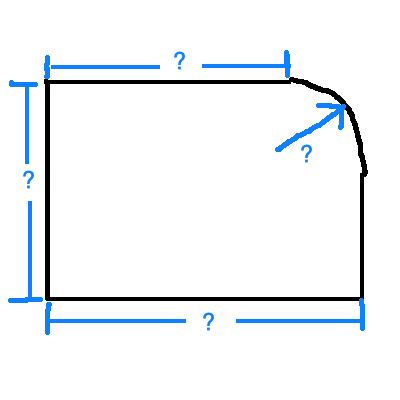

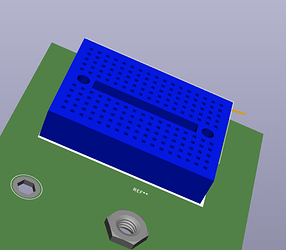

Kicad’s 3D-Viewer…

PDF of Copper_Btm (small 2kb)

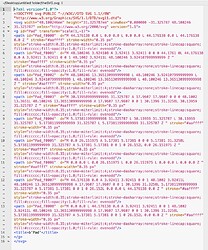

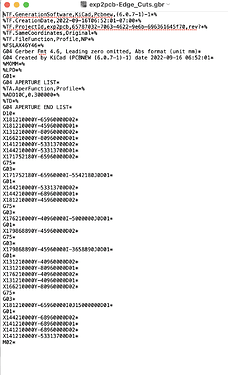

The SVG

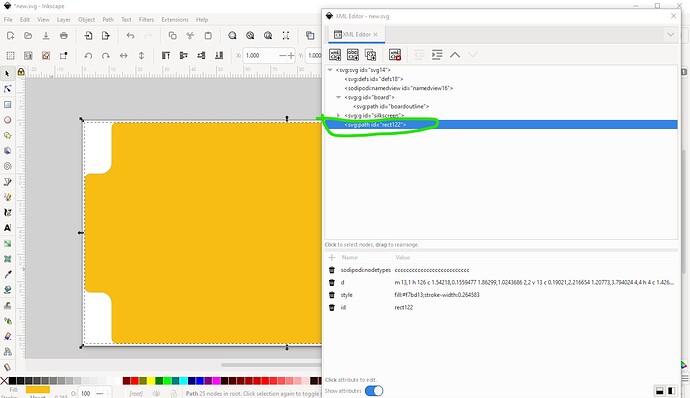

Screenshot of theSVG (to confirm Not creating Layers…)

For Fun, I loaded the Gerbers into CopperCAM (the program I use for CNC Milling PCB’s)

I did NOT setup any parameters (that would be needed for actual machining (tool bits, drill diameters…etc)). Just did it to do a Full Confirmation…

As you can see, All works Well!