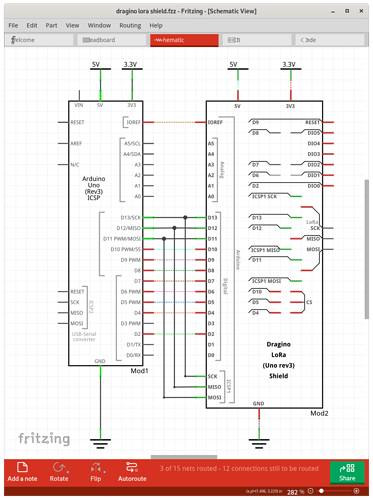

Here is what should be a fully functional version of the shield friendly uno and Dragiono LoRa parts. Bugs allowing. I did not fill in the shield breadboard graphics beyond what was useful for identifying the functional parts. The focus was on getting the schematic view layout into what (to me) was a more logical structure. Inputs to the shield (the Arduino pins) on the left, power and ground top and bottom, shield specific IO on the right. No duplication of bused connections, no connections on the shield for pins that are never used (directly) by the shield. After some iterations, I found a reasonably clean way of showing the shield configuration / settings jumpers internal to the main schematic symbol block. Both sketch and part files included, so you do not need to extract from the sketch. To get the schematic to work this way, with the LoRa ICSP as a output, I needed to duplicate (and bus) the connections for use with the internal configuration connections.

dragino lora shield.fzz (42.0 KB)

arduino_uno_for_shields.fzpz (27.5 KB)

dragino_lora_shield.fzpz (10.4 KB)

Here is an image of the schematic view with (just) enough real wires to get the rest of the ratsnest wires to go to reasonable locations.

Discussion open for this style of doing the layout.