It’s similar to PJ398sm which @vanepp has made in the past.

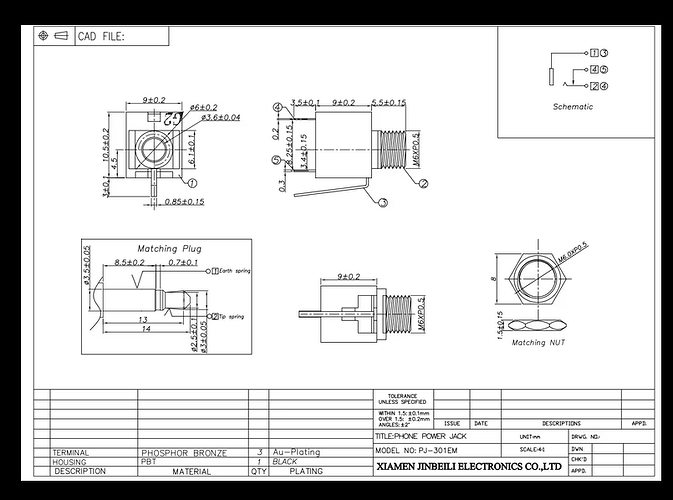

This is as close to a proper spec sheet I could find. The pins fit in 1.1 mm holes, so well within tolerance. EDIT: my test was to place it in a pcb where the pins (5 in a row) accomodate it.

Another variant, with nearly the exact same name (PJ-301M-12) is identical but for having slightly wider pins (1.3 mm in comparison with 1 mm).

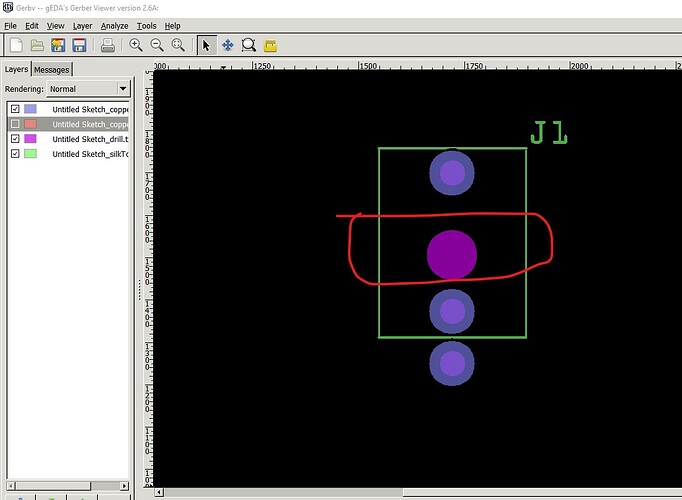

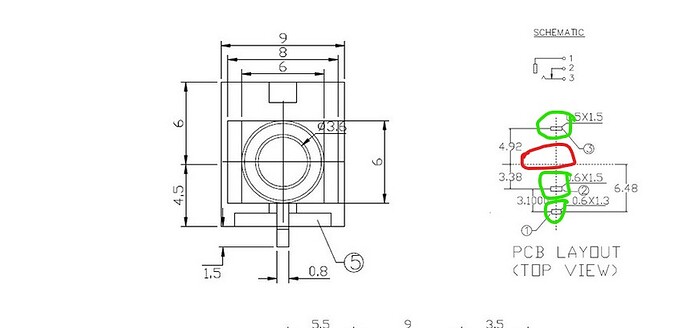

Easy enough to make one. I see in the PJ398sm that there is an extra hole where the Jack enters (circled in red here)

Does the PJ-301M need that hole? The Thonkiconn part here:

https://www.thonk.co.uk/shop/thonkiconn/

has a pcb layout which does not show the extra hole and it is (as of Fritzing 1.0.2 I think) now possible to cut slots in parts although I expect a 1.1mm hole is a better bet (for people with older Fritzing versions, and possibly board houses that can’t cut slots if there are any.)

I’ll make a part with 1.1mm holes for the pins.

Peter

The hole isn’t needed, since it’s easy to route around. The thonk guys are exercising an abundance of caution

Very kind of you to take it on! One day I’ll have to spend some time making parts. But I’m swamped !

Thanks!

This part should do what you want.

PJ-301M.fzpz (4.1 KB)

Peter

1 Like

Thanks! That will definitely work.

The holes are the better solution in any case. How does one do slots? I’ve only ever edited the one part (expanding the pads on a button). Does one simply draw a pad as a rectangle?

EDIT: I ask since I’d like to fix the 5 pin 3.5mm stereo jack which always sits crooked in it’s current form.

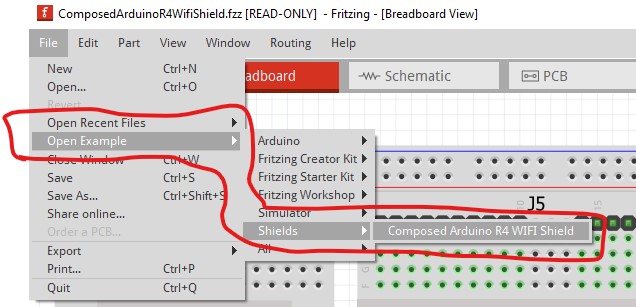

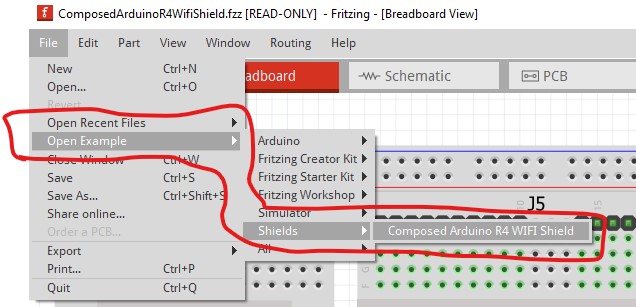

It is a little complex, in the part you need to add an outline svg like you were cutting a slot in the pcb (the requirement of the path is documented, it needs to be a single path formed via a differential union.) You didn’t used to be able to do this in parts only a sketch but in one of (I think!) the 1.0 versions they added it to parts. I don’t think the part will work in older versions of Fritzing though as they didn’t support slots in parts. There is an example part available in the examples directory here:

Peter

1 Like

Ok, thanks for the tip. I’ve just started making small breakout boards (for a vactrol, for pots and so on) and it’s a good opportunity to test making parts for production without it costing a fortune or wasting too much material!