Indeed they are in addition to number of other problems. For hole sizes, assuming Inkscape (I think the others. at least Corel Draw, are different), hole size is calculated by hole size = Diameter of pad - (2 * stroke-width) . So to get a .038in hole suitable for a .1 header pin, and assuming a standard 20 thou stroke-width and standard scale (none of which are true in the original  ), the calculation is pad diameter = 0.078in, stroke-width 20, so 78 - 40 = 38 (in thou) or 0.038in for the hole. This will work at any scale, the math is just more difficult at incorrect scales. The other major problem in the original is the lack of schematic terminalIds which causes the connection to the middle of the pin like this )the top one is the original part without terminalIds)

), the calculation is pad diameter = 0.078in, stroke-width 20, so 78 - 40 = 38 (in thou) or 0.038in for the hole. This will work at any scale, the math is just more difficult at incorrect scales. The other major problem in the original is the lack of schematic terminalIds which causes the connection to the middle of the pin like this )the top one is the original part without terminalIds)

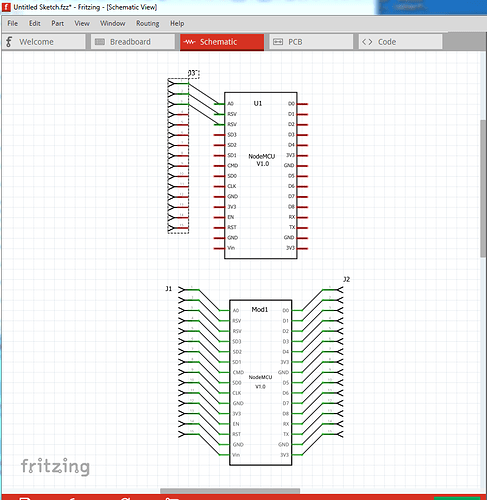

Also the pins are out of sequence (they jump at around pin 20 to the 32 range) and the scale of the svgs are all incorrect. I fixed all of that up in this new part, which is ready to submit to core parts when someone gets around to doing so:

NodeMCU V1.0-1.fzpz (9.8 KB)

This has a new moduleId and family and will thus load beside the one above for comparison.

Peter