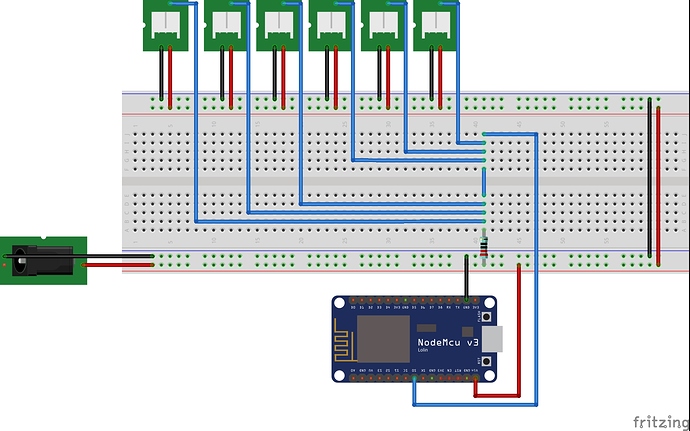

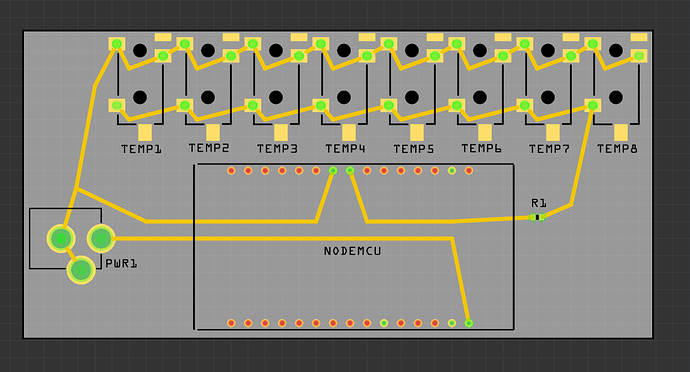

Since the temperature sensor connectors used are all just jumpers / headers, I can not confirm that the power, ground, and data lines are being connected to the right pins when the sensors are actually attached. I can say that the connections are consistent, with the 3 lines going to the same pin of every jumper on the breadboard view.

When Initially loading the sketch file, I confirmed there is a wiring error someplace, because, on breadboard view, clicking (and holding) on one of the power or ground lines high lighted all of both the power and ground connections and breadboard rails. Fritzing sees them shorted together.

They are still shorted together after all of the wires in schematic view are deleted (Routing menu, select all traces, delete). Restoring those traces (undo), and doing the same in the pcb view also shows that power ground are shorted. Deleting all traces on both the schematic and pcb views gets rid of the short.

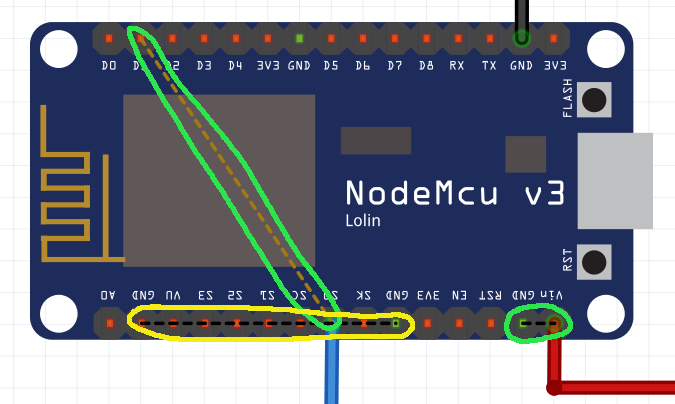

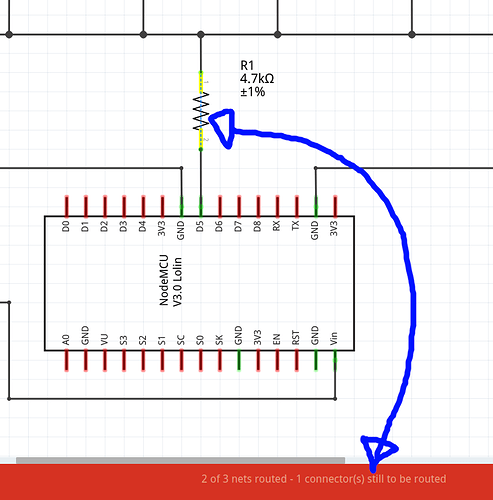

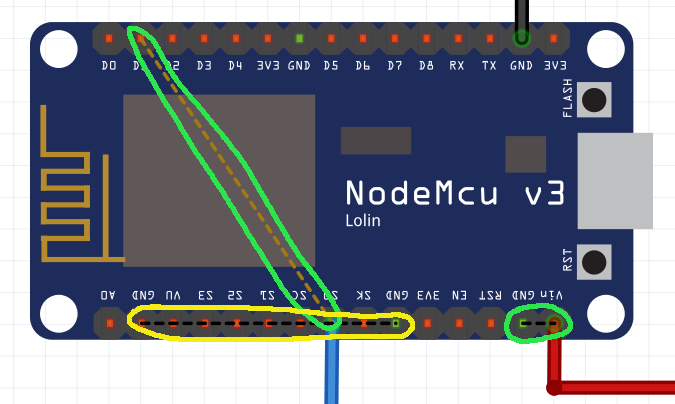

Hovering the mouse over the first (left) BB sensor connection shows that it is JP1. Hover over the connection point with the black wire, which is connected (through the breadboard rail) to NodeMcu GND, show that it is pin 1. Going to the schematic view and hovering the mouse over JP1, and the connection labeled one, shows that is also pin 1. Following the trace from that pin (down, right, down, right) leads to NodeMCU Vin. Not ground. Same thing on pcb view. Starting from JP1, pin 1, the trace leads to Vin. Not ground.

So either both schematic and pcb have the power and ground reversed, or the breadboard view does. Without knowing which lead of the actual sensor is connected to each pin of the header, there is no way to tell which is right or wrong.

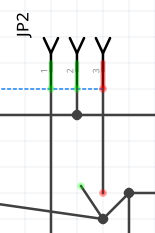

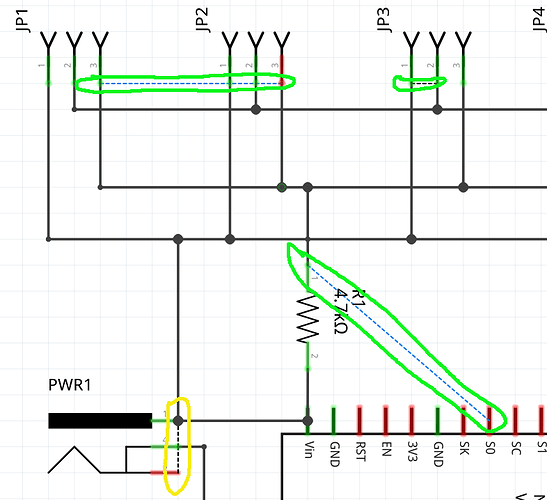

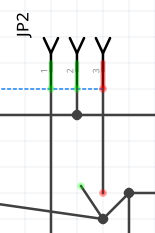

There are other problems, at least on schematic view. JP2, pin 3 is shown in red. That means it is not actually connected. The trace looks like it goes there, but it does not actually connect to the rest of the circuit. The problem is that the trace coming from pin 3 does not connect where looks like. This can be seen by moving the node where the traces appear to join, discovering what looks like another join/bend point, and attempting to move that as well. Which discovers that the 2 traces do not actually connect.

Schematic and Breadboard are inconsistent another way. On breadboard view the sensor data lines are connecting to NodeMCU pin SO. On schematic (and PCB) view, they connect to D1.

The ratsnest wires (dashed lines) on each view provide hints of these problems. A ratsnest wire is shown on a view when one of the OTHER views has an actual wire/trace between the pins that does not exist on the current view.

The yellow circle ratsnest above is in indication of an error in the NodeMCU part itself. The Ground pins are not connected internally.

The circled BB ratsnest above indicates another problem. Details on schematic view.

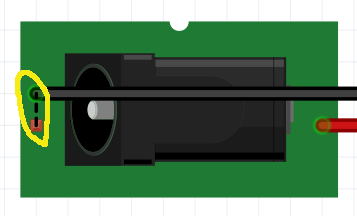

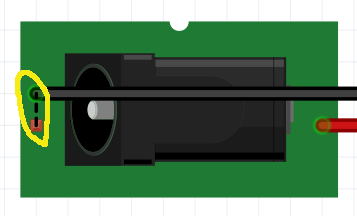

The ratsnest wire between pin 3s of JP1 and JP2 is another indication of the broken connection described above. The yellow circle on the PWR1 part shows the reason for the matching one on the BB view. There are 3 connection pins. 2 of them form a switch that is open or closed depending whether a plug is in the socket or not. On schematic view, you are connecting to the pin that is open when the power is plugged in. The ground connection should be to the bottom connection.

Going back to the initial tests, on BB view, deleting all of the wire gets rid of the power to ground shorts on the other views. As said above, need to know which sensor lead goes to which header pin to tell which is correct.