Introduction – Sometimes when I bread board a circuit, one of the circuit components has non-standard 100 mil pin spacing. This situation causes a problem when using the white MB-102 solderless bread boards. I have used 4-inch jumper wires with socket ends to connect to the component pins and pin ends to plug into the bread board. This connection scheme works. However the component rolls around on the breadboard and sometimes one or more of the jumper wires pulls out during the bread board testing process.

Improved Connection Method – I was looking for a means to connect the component with non-standard pin spacing to the bread board in a solid mechanical/electrical connection with a short length rigid connection method.

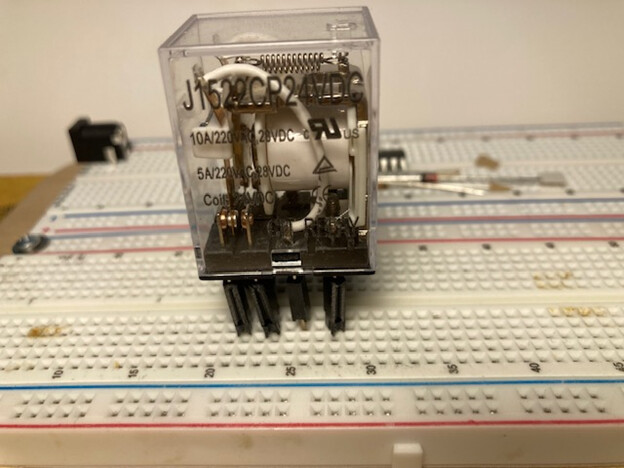

This problem arose when I tried to connect a CIT, J1522CP24VDC relay into my bread board circuit.

Such a connection for this relay can easily be made by using long-tail socket pins, cut from a long-tail socket header. The overall long-tail socket header length provides a simple means to make the connection between the relay and the bread board. The long-tail socket header length allows me to swing the socket pin tail around to easily accommodate the non-standard pin arrangement on the relay.

Long-Tail Socket Header - The following photograph shows the type of long-tail socket header used for this connection along with socket pins cut from the header to be used for this connection purpose.

Relay Connected to Bread Board – The following photograph shows the J1522CP24VDC relay connected to the bread board, in a solid, rigid connection method.

The relay doesn’t wobble on the breadboard using this connection method.