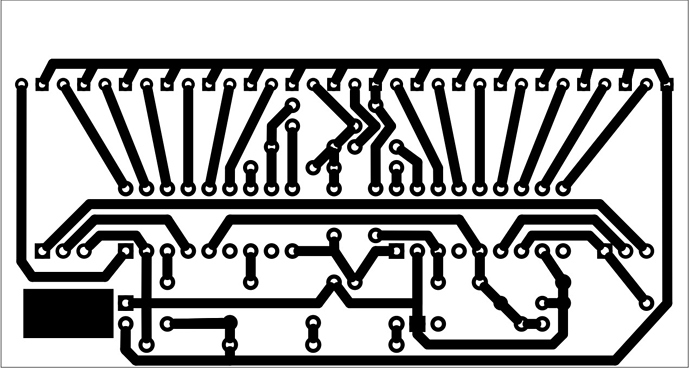

Steps I took that resulted in the problem:

When I set my tracks to “extra thick” and the dome ends of tracks overlap into the holes, so that they aren’t round anymore.

I’m using the toner transfer method so round holes would help guide the drill.

…

What I expected should have happened instead:

…

My version of Fritzing and my operating system:

…

Please also attach any files that help explaining this problem

It seams that you have to save it, close the project, re-open it, and the holes become round.

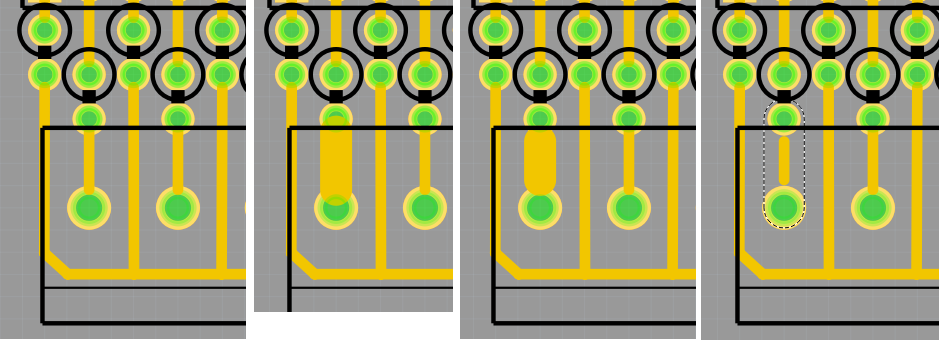

This fixes the holes, but now the traces with their round ends don’t make contact with the pads that well when traces are at 45º, so that they are necked down before the pad.

Was looking for this for the past few days.

Here’s my example with print screens.

It looks like the traces are first drawn from pad to pad (copper around the hole). Which is good at 24mil thickness.

If you make an adjustment in width, the trace line is enlarged around what is already there, without correcting for length, hence covering the holes partially. This isn’t the problem for me; on the contrary:

When you quit Fritzing and reopen, all the traces are redrawn from pad to pad (not covering the holes). If you reduce width at this point, it will lose contact with the copper altogether.

So my issue is that all the widened traces become less in contact with the pads, like you mentioned.

I think the solution here would be to adjust the “roundness” of the trace ends, instead of making them a half-circle they could be rectangular with rounded edges.