Hi everyone,

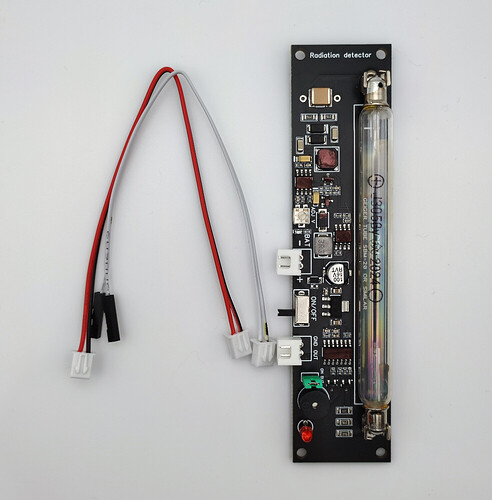

I’ve just finished creating a part for the GGreg20_V3 Ionizing radiation detector (Geiger counter) by IoT-devices. This is my first time creating a complex part with custom PCB and Breadboard views, and I’m sure there are some technical issues under the hood (SVG scaling, terminal points, or XML structure).

The module has 4 pins (BAT-, BAT+, GND, OUT). I’ve tried to follow the copper1 → copper0 hierarchy for the PCB view and used a black rectangle for the silk mask.

Could someone please run this through the FritzingCheckPart script and check if the connectors are properly aligned and the SVG code is clean?

Any feedback or “fixed” version of the file would be greatly appreciated! If possible, could you please provide a corrected .fzpz file with the necessary fixes, as I’m still learning the technical requirements?

Best Regrds,

Oleksii Yanko

co-founder

IoT-devices LLC

Kyiv, Ukraine

Name of the part❗

GGreg20_V3 - DIY Geiger counter module

Your previous work, similar parts

In case there are similar Fritzing parts, or you already started work, please link it here.

- I’ve created part by my own. See below.

Top view❗

The part file to check:

IoT-devices GGreg20_V3 Geiger counter.fzpz (39.4 KB)

Datasheet❗

The official documentation of the part manufacture is linked here:

As a new forum user, I am unable to add multiple images. I am also unable to add a link to the module description, but it almost exactly matches the Datasheet PDF. Therefore, please write to me and I will provide the necessary additional information.

Footprint

Does not apply to breakout boards.

Type

I did not read this

Breakout board, sub assembly, plug in module (A)

Antenna (AE)

Battery (BT)

Capacitor (C)

Diode (D)

Display (DS)

Fuse (F)

Hardware , mounting screws, etc. (H)

Jack, fixed part of a connector pair, header (J)

Relay (K)

Inductor, Coil, Ferrite bead (L)

Loudspeaker, Buzzer (LS)

Motor (M)

Microphone (MK)

Plug, moveable part of a connector pair (P)

Transistor (Q)

Resistor (R)

Thermistor (RT)

Varistor (RV)

Switch (S)

Transformer (T)

Integrated Circuit (IC)

Crystal, Oscillator (Y)

Zender diode (Z)

Other (please specifiy)