Hi all =]’

I’ve being Investigating FZ features for some time in order to learn how to create some artistic boards I have in mind and I stuck upon some annoying issue: I’d like to create custom soldermask that doesn’t necessarily related to other features of a part like copper connections placement and, for the life of me, couldn’t get it to work.

Let’s get technical:

This picture ( https ://imgur.com/a/JR6j3ZJ ) shows a regular image on PCB using the built-in part that lets you pick a picture and it’ll make it onto the PCB’s copper layer. Note that most of the Iron Man there is covered in soldermask. To the left you can see a part used as soldermask remover (after nights of digging the web and the forums on how to remove soldermask and countless attempts and edits to SVG files) that removes the whole soldermask effect from the area in question.

The problem is that it is two different parts and therefore needs alignment and some other small problems arise.

Since this problem rose from a artistic demand, my ultimate favorable workflow would be something like this: working on some picture in AI, setting up the layers conveniently for FZ then creating a single part that will include complex copper and soldermask areas placement.

I will note before I ask my questions that I viewed almost every available YouTube video I could lay my hands on and couldn’t find the answers, the forums were a lot more helpful but still couldn’t make it to the final stretch.

Since I’ve seen some advanced people around here knowing deeply how FZ works and analyzes the SVG’s we feed into him, here’s my questions:

1.) What layers does FZ actually process? what is the structure of the SVG should be like?

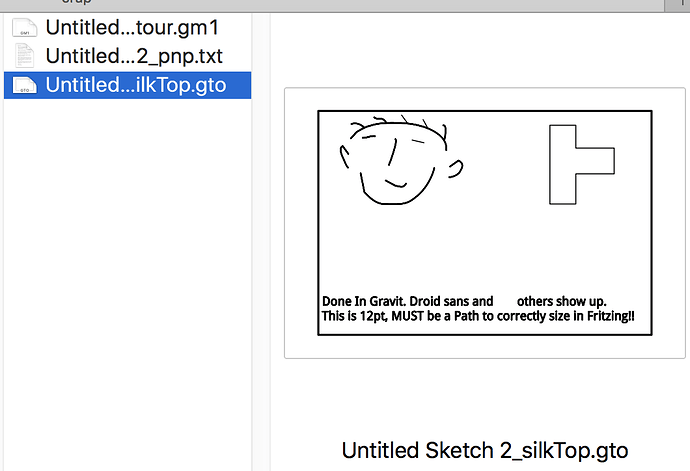

here’s a picture of an example SVG for PCB tab/layer/section found on FZ website as instructional material ( https://imgur.com/a/EXRuxJp ) - after opening several hundreds of part files submitted by the community, still haven’t seen dominant layer structure or grouping order. Some file had the copper1 layer inside 20-layer cascaded groups, some had none. No matter what I did in the ‘soldermask’ layer, it didn’t have any seen effect in FZ or Gerber exports.

2.) I’d like to know which tags inside the SVG file is relevant to FZ and what they does. In this picture ( https://imgur.com/a/8LKNi6r ) you can an example file opened in Sublime and I don’t know what all the tags mean in the start of the file. For example, I did notice that I need to add " fill-rule=“evenodd” clip-rule=“evenodd” " to parts that I created to use as soldermask remover.

3.) I’ve notice that if the order of the layers is different, there are variations in the results after importing to FZ Parts Editor, for example if copper0 & copper1 is switched, it messes with the top layer in one case and not in the other, so- Is there any particular order all the various layers should be at?

I know I came in here and for my first post I’ve bombarded you with questions but I really desperate after all the digging…I’ve wanted to add files to prove my various points but since I’ve done hundreds of tests and Gerber exports very fast while I was working on it, it is very hard right to find specific files so if you guys would ask for files about specific incident, I will generate new files for your questions and post them for you to see.

Thank you so much, everyone!

Kimkash