These seems to need some work yet to be usable.

I ran the first of those, the cmnb6-a-base, through FritzingCheckPart. I did not check in detail, but here are some highlights.

terminalId entries are in the the fzp definitions for schematic view, but the matching id values are not in the svg file. With the schematic image as is, the terminal Ids are not needed. However, the schematic images are very non-standard. They have circular connectors like breadboard and pcb. Schematic is normally created with 0.1 connector inch lines extending out from the body of the part, and not using the green background for the body. In that format, the terminal id elements should exist, and should be at the outer end of the matching connector line.

Schematic is a “logical” representation. It does not care about things like mounting holes, row spacing, connector pin hole and copper size.

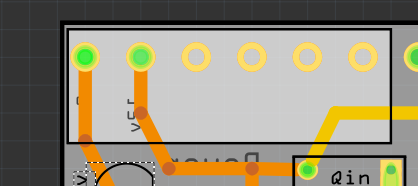

There are duplicate connector«number»pin elements in the pcb. Quick guess: you have separate copper0 and copper1 groups, with a copy of the connectors in each. Instead, the copper0 layer (group) should be inside the copper1 group, and the connectors only inside the copper0 group. Since copper0 is inside copper1, a single connector element is then in both copper groups.

The B, C, D variants load as blank blocks, without any connectors at all. Is that intended?

DIN-9, A/Base breadboard has more pins shown than schematic or PCB, but right side bottom 2 blocks of pins are not active. They are just part of the image, without any functionality. For screw terminal, the PCB seems to have the extra pins active, but not breadboard, and they do not exist at all in schematic.