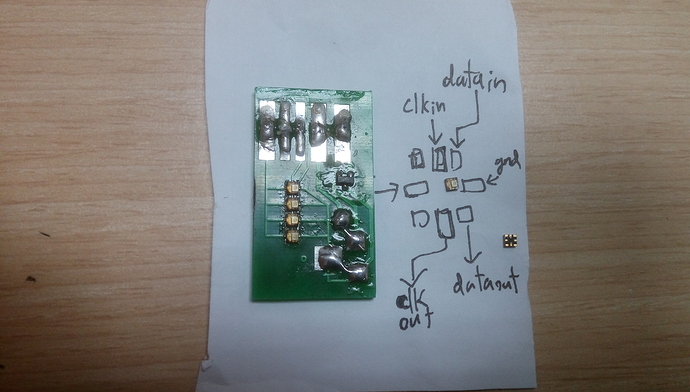

Here is my working prototype. With my “pads part”

Footprint, one can find the board from the APA-102-2020 - the ultimate smd addressable led.

The package is distinguishable from top,but can’t from bottom

There’s IC implanted in right side of the chip,

And leds in the left.

The density is 4LED/cm

Hopefully could be as dense as 5/cm, with specialized footprints

But there are power pins on the side of the package so I’m afraid of shortage

edit: from observations, the Din/Cin and Dout/Cout were inverted in your footprints,

just need to switch label Din<->Dout, and Cin<->Cout