thanks for your awareness, I know, and power was planned to be separated with N-channel mos

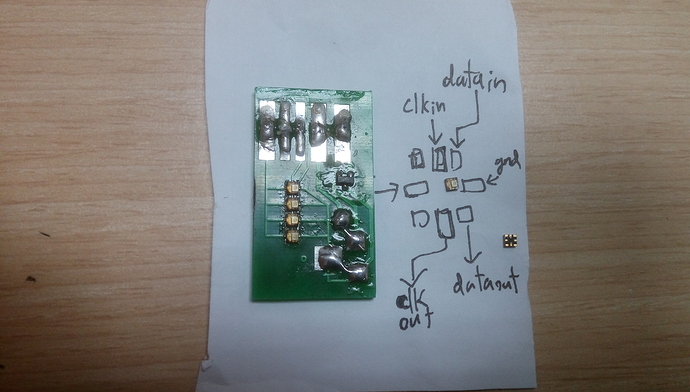

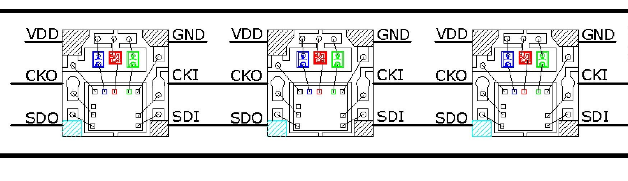

Apa102 were widely used in POV projects, mostly sold in 5050 package LED strips

and this is not my first POV, likely 5th if i count.  2020 is not friendly for hand solder,

2020 is not friendly for hand solder,

got a hot air gun&paste and already experienced with success air-soldering

I pick 2020 because it’s small, can do dense POV, and its simple integrated driver

with a 18650 Lithium battery I got my POV with 72 apa102 -5050LEDs working well

I hope 100s of them, in 2020, work well too,

If not, I’ll parallel a second battery,

oh about part creation,

maybe I just can’t hold inkscape crashing all the time,

I can draw my own board shape(and inkscape mess it up often)

but part’s kinda much for me yet

breaking up to pads works well with easy/small parts to me,

most likely due to I use strange parts, such like some switchs(like those in hand-flashlights) , they dont have pins or leads, not a PTH/SMD part in general.

and needs custom designed pads for soldering, depends on how I’m using them.

@Old_Grey sure, select all trace and change

are there group and layer like those features in PS/Sketchup/CAD in Fritzing?

if not, its still kinda better for me to set traces for each in this case,

I got my power lines as wide as possible, and SPI lines to 8-12 mils as they’re under the part, short and don’t need to be wide.

thanks for all

2020 is not friendly for hand solder,

2020 is not friendly for hand solder,