Thanks. My more general point was, how do you know what these are? I DID check the generic parts bin - I used the ‘search’ box and those six caps popped up. Oddly, they mention Sparkfun, but I did try the search function as there are a ton of parts.

I see your point, I should navigate manually to the core bin - thank you! That helps.

Now, you’re going to laugh - I skimmed the ‘core’ parts but didn’t see a 220uF cap and saw no way to edit the part or lead spacing. doh there is a .22mF cap. lolz.

Honestly, I’m just working backwards - I’m building a circuit board for a friend, and just trying to find what parts Frizing has that he can then order, not necessarily trying to fit a specific part to Fritzing. For those kinds of activities, I’ve already edited parts. It just seemed to me for passive’s I should be able to pick standard stuff out of the bin.

My question really was just “how are you supposed to know?” In the capacitor part there was no key to the different sizes. If I’m expected to place a sample, go to the PCB view, examine the board, and try to figure out what I got … EACH PART I PLACE, this is going to be a real hassle, except possibly for throwing together some Arduino projects.

I tried Eagle, but I thought Fritzing was easier to use.

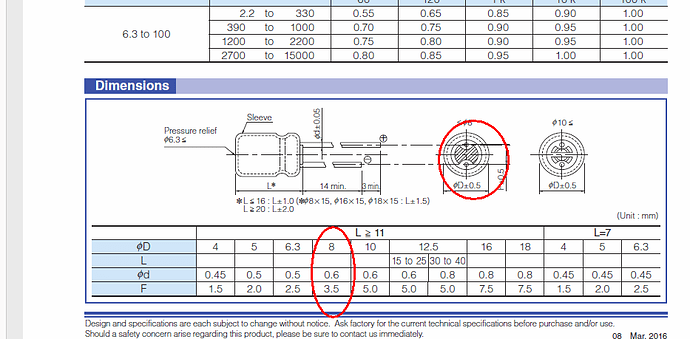

Regarding the ‘standard’ lead spacing, honestly, that’s the kind of stuff I don’t know; I’m an EE but haven’t worked in the industry in a while (into software now) so off the type of my head don’t know what is “Standard”. SO I did check the data sheet  on page 12, caps with a diameter of 8 have a spacing of 3.5.

on page 12, caps with a diameter of 8 have a spacing of 3.5.

Then, the 220uF, 25V cap:

I’m a n00b and can’t put two images - point is the 220uf cap at 25V is a 8x11 cap - thus the 3.5.

Still, it’s through hole, so even if I source a 3.5mm it’ll solder fine with 5mm.

Thanks for the advice, I appreciate it!

== John ==

on page 12, caps with a diameter of 8 have a spacing of 3.5.

on page 12, caps with a diameter of 8 have a spacing of 3.5.