Hi everybody,

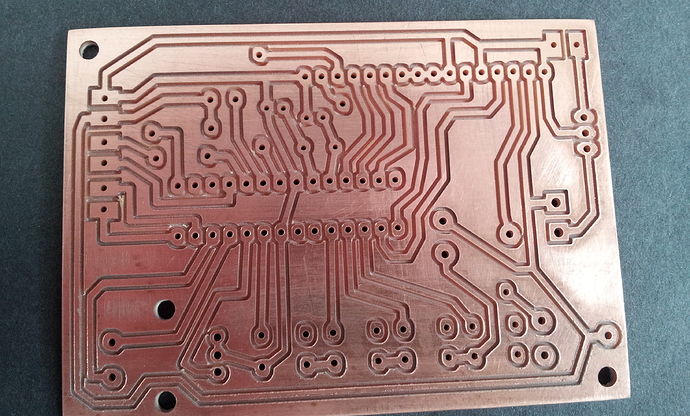

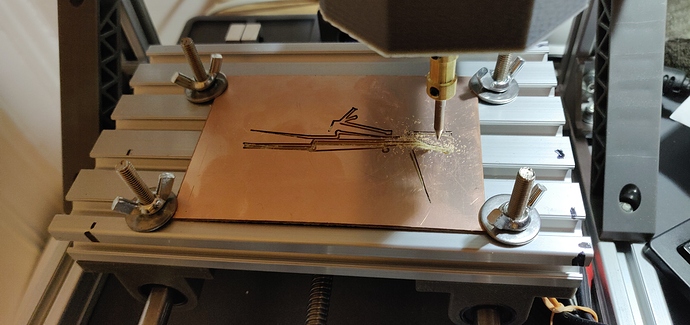

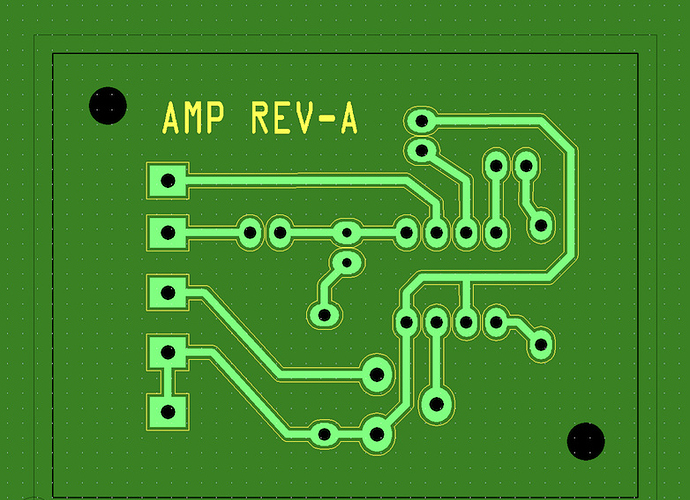

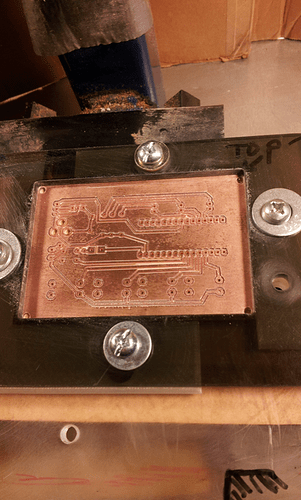

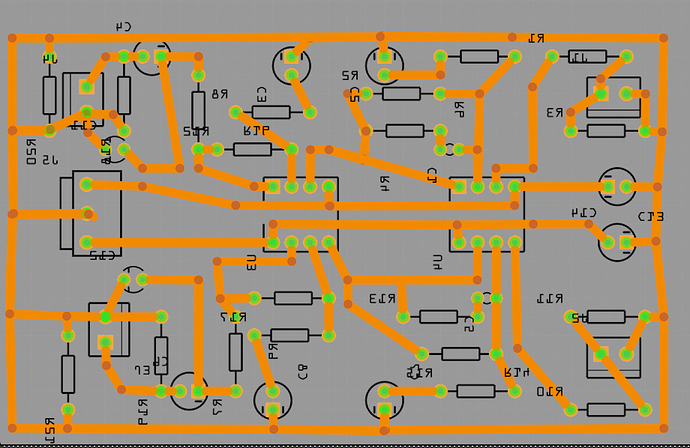

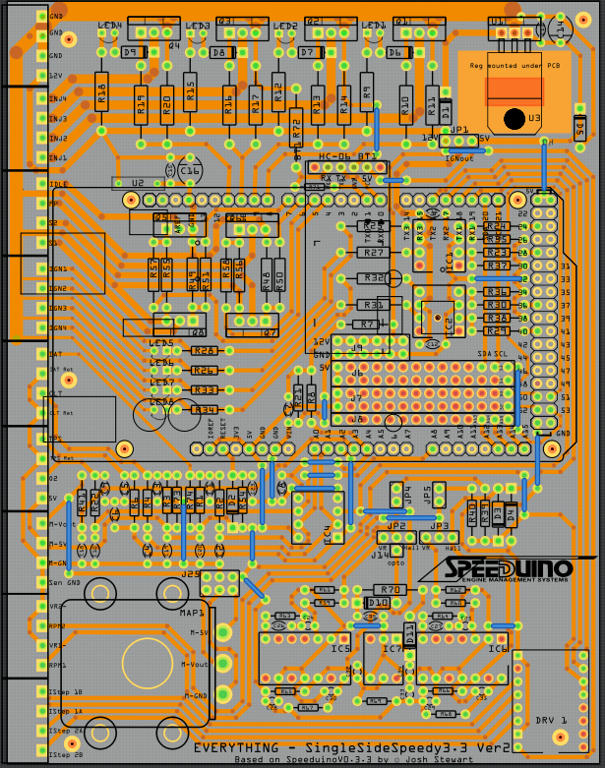

First post here, I created a pcb for a preamp. I used a process found on Instructables (link below) and have a lot of errors when I am trying to machine it. I am trying to find out if there is something wrong I did in the software, or something wrong with my cnc ( cheap 1610)

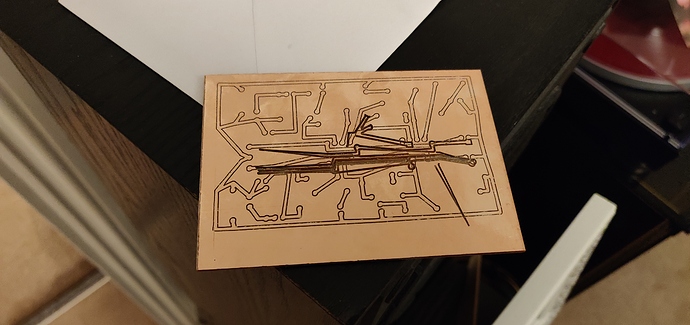

The first test with a simple circuit was fine only that the traces were to small.

I designed the preamp pcb , exported , done all the steps, fire up the cnc and after it milled a few traces I realized that I forgot to enlarge the traces but the program seemed to run fine, re-done all traces extra-thick, and tried again. This time the machine would not follow the lines and I got a lot of lines with Error 33. I run the code on an online emulator and all seemed ok . I’ve been working on electronics for a long time but I am a beginner with cad and CNC. I understand the error is related to arches but everything else is above my knowledge now

I can upload the code and pcb later today after I get home.

Thank you in advance